PDF Publication Title:

Text from PDF Page: 061

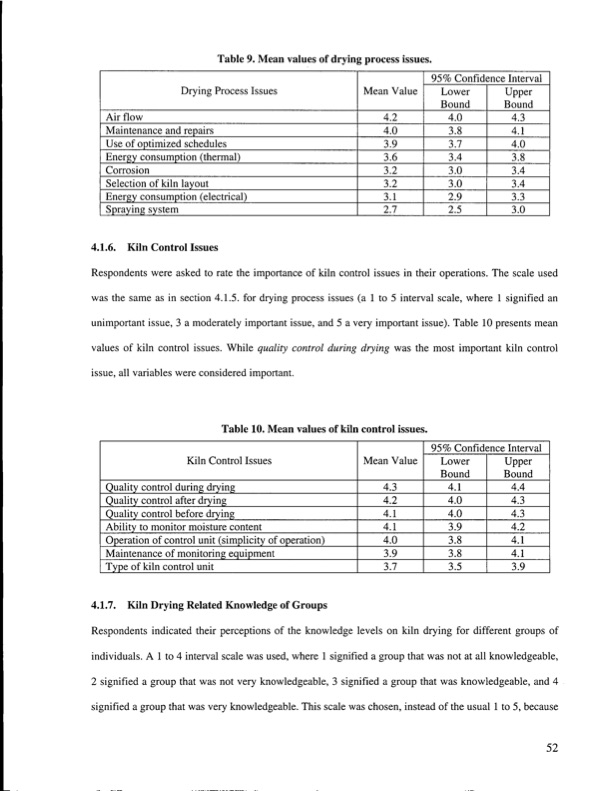

Drying Process Issues Air flow Maintenance and repairs Use of optimized schedules Energy consumption (thermal) Corrosion Selection of kiln layout Energy consumption (electrical) Spraying system Mean Value Lower Bound Upper Bound Kiln Control Issues Quality control during drying Quality control after drying Quality control before drying Ability to monitor moisture content Operation of control unit (simplicity of operation) Maintenance of monitoring equipment Type of kiln control unit Mean Value 4.3 4.2 4.1 4.1 4.0 3.9 3.7 Lower Bound Upper Bound Table 9. Mean values of drying process issues. 4.1.6. Kiln Control Issues Respondents were asked to rate the importance of kiln control issues in their operations. The scale used was the same as in section 4.1.5. for drying process issues (a 1 to 5 interval scale, where 1 signified an unimportant issue, 3 a moderately important issue, and 5 a very important issue). Table 10 presents mean values of kiln control issues. While quality control during drying was the most important kiln control issue, all variables were considered important. Table 10. Mean values of kiln control issues. 4.1.7. Kiln Drying Related Knowledge of Groups Respondents indicated their perceptions of the knowledge levels on individuals. A 1 to 4 interval scale was used, where 1 signified a group that was not at all knowledgeable, 2 signified a group that was not very knowledgeable, 3 signified a group that was knowledgeable, and 4 signified a group that was very knowledgeable. This scale was chosen, instead of the usual 1 to 5, because 95% Confidence Interval 4.2 4.0 4.3 4.0 3.8 4.1 3.9 3.7 4.0 3.6 3.4 3.8 3.2 3.0 3.4 3.2 3.0 3.4 3.1 2.9 3.3 2.7 2.5 3.0 95% Confidence Interval 4.1 4.4 4.0 4.3 4.0 4.3 3.9 4.2 3.8 4.1 3.8 4.1 3.5 3.9 kiln drying for different groups of 52PDF Image | KILN DRYING PROBLEMS AND ISSUES IN CANADA

PDF Search Title:

KILN DRYING PROBLEMS AND ISSUES IN CANADAOriginal File Name Searched:

ubc_2004-0049.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |