PDF Publication Title:

Text from PDF Page: 074

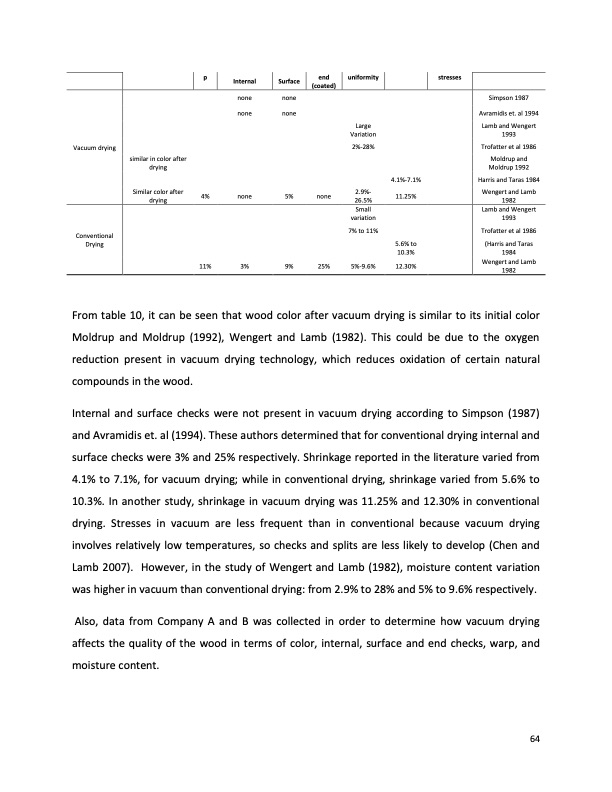

p Internal none none none 3% Surface end (coated) none none 5% none 9% 25% uniformity Large Variation 2%-28% 2.9%- 26.5% Small variation 7% to 11% 5%-9.6% stresses Vacuum drying Conventional Drying similar in color after drying Similar color after drying 4% 11% 4.1%-7.1% 11.25% 5.6% to 10.3% 12.30% Simpson 1987 Avramidis et. al 1994 Lamb and Wengert 1993 Trofatter et al 1986 Moldrup and Moldrup 1992 Harris and Taras 1984 Wengert and Lamb 1982 Lamb and Wengert 1993 Trofatter et al 1986 (Harris and Taras 1984 Wengert and Lamb 1982 From table 10, it can be seen that wood color after vacuum drying is similar to its initial color Moldrup and Moldrup (1992), Wengert and Lamb (1982). This could be due to the oxygen reduction present in vacuum drying technology, which reduces oxidation of certain natural compounds in the wood. Internal and surface checks were not present in vacuum drying according to Simpson (1987) and Avramidis et. al (1994). These authors determined that for conventional drying internal and surface checks were 3% and 25% respectively. Shrinkage reported in the literature varied from 4.1% to 7.1%, for vacuum drying; while in conventional drying, shrinkage varied from 5.6% to 10.3%. In another study, shrinkage in vacuum drying was 11.25% and 12.30% in conventional drying. Stresses in vacuum are less frequent than in conventional because vacuum drying involves relatively low temperatures, so checks and splits are less likely to develop (Chen and Lamb 2007). However, in the study of Wengert and Lamb (1982), moisture content variation was higher in vacuum than conventional drying: from 2.9% to 28% and 5% to 9.6% respectively. Also, data from Company A and B was collected in order to determine how vacuum drying affects the quality of the wood in terms of color, internal, surface and end checks, warp, and moisture content. 64PDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |