PDF Publication Title:

Text from PDF Page: 008

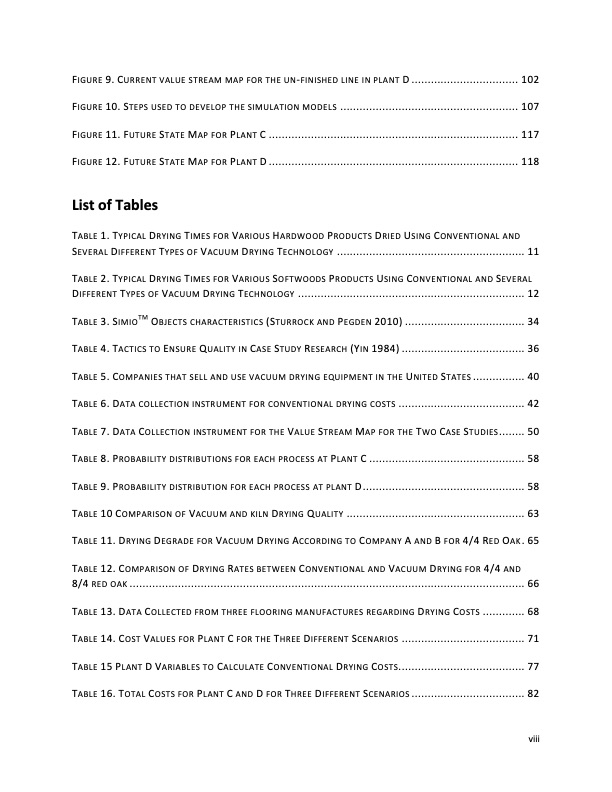

FIGURE 9. CURRENT VALUE STREAM MAP FOR THE UN-FINISHED LINE IN PLANT D ................................. 102 FIGURE 10. STEPS USED TO DEVELOP THE SIMULATION MODELS ....................................................... 107 FIGURE 11. FUTURE STATE MAP FOR PLANT C ............................................................................. 117 FIGURE 12. FUTURE STATE MAP FOR PLANT D ............................................................................. 118 List of Tables TABLE 1. TYPICAL DRYING TIMES FOR VARIOUS HARDWOOD PRODUCTS DRIED USING CONVENTIONAL AND SEVERAL DIFFERENT TYPES OF VACUUM DRYING TECHNOLOGY .......................................................... 11 TABLE 2. TYPICAL DRYING TIMES FOR VARIOUS SOFTWOODS PRODUCTS USING CONVENTIONAL AND SEVERAL DIFFERENT TYPES OF VACUUM DRYING TECHNOLOGY ...................................................................... 12 TABLE 3. SIMIOTM OBJECTS CHARACTERISTICS (STURROCK AND PEGDEN 2010) ..................................... 34 TABLE 4. TACTICS TO ENSURE QUALITY IN CASE STUDY RESEARCH (YIN 1984) ...................................... 36 TABLE 5. COMPANIES THAT SELL AND USE VACUUM DRYING EQUIPMENT IN THE UNITED STATES ................ 40 TABLE 6. DATA COLLECTION INSTRUMENT FOR CONVENTIONAL DRYING COSTS ....................................... 42 TABLE 7. DATA COLLECTION INSTRUMENT FOR THE VALUE STREAM MAP FOR THE TWO CASE STUDIES........ 50 TABLE 8. PROBABILITY DISTRIBUTIONS FOR EACH PROCESS AT PLANT C ................................................ 58 TABLE 9. PROBABILITY DISTRIBUTION FOR EACH PROCESS AT PLANT D.................................................. 58 TABLE 10 COMPARISON OF VACUUM AND KILN DRYING QUALITY ....................................................... 63 TABLE 11. DRYING DEGRADE FOR VACUUM DRYING ACCORDING TO COMPANY A AND B FOR 4/4 RED OAK . 65 TABLE 12. COMPARISON OF DRYING RATES BETWEEN CONVENTIONAL AND VACUUM DRYING FOR 4/4 AND 8/4 RED OAK .......................................................................................................................... 66 TABLE 13. DATA COLLECTED FROM THREE FLOORING MANUFACTURES REGARDING DRYING COSTS ............. 68 TABLE 14. COST VALUES FOR PLANT C FOR THE THREE DIFFERENT SCENARIOS ...................................... 71 TABLE 15 PLANT D VARIABLES TO CALCULATE CONVENTIONAL DRYING COSTS....................................... 77 TABLE 16. TOTAL COSTS FOR PLANT C AND D FOR THREE DIFFERENT SCENARIOS ................................... 82 viiiPDF Image | Impact of Vacuum-Drying on Efficiency of Hardwood Products

PDF Search Title:

Impact of Vacuum-Drying on Efficiency of Hardwood ProductsOriginal File Name Searched:

Brenes_Angulo_OM_T_2014.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |