PDF Publication Title:

Text from PDF Page: 100

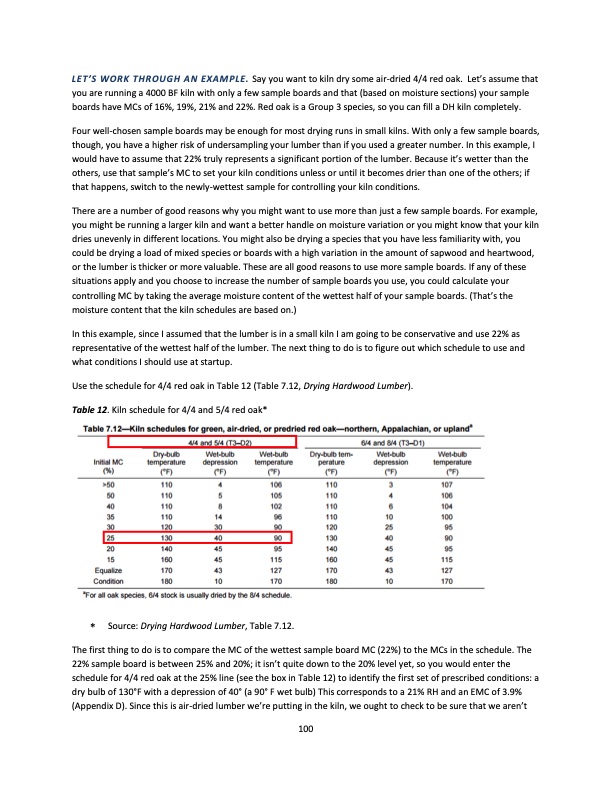

LET’S WORK THROUGH AN EXAMPLE. Say you want to kiln dry some air-dried 4/4 red oak. Let’s assume that you are running a 4000 BF kiln with only a few sample boards and that (based on moisture sections) your sample boards have MCs of 16%, 19%, 21% and 22%. Red oak is a Group 3 species, so you can fill a DH kiln completely. Four well-chosen sample boards may be enough for most drying runs in small kilns. With only a few sample boards, though, you have a higher risk of undersampling your lumber than if you used a greater number. In this example, I would have to assume that 22% truly represents a significant portion of the lumber. Because it’s wetter than the others, use that sample’s MC to set your kiln conditions unless or until it becomes drier than one of the others; if that happens, switch to the newly-wettest sample for controlling your kiln conditions. There are a number of good reasons why you might want to use more than just a few sample boards. For example, you might be running a larger kiln and want a better handle on moisture variation or you might know that your kiln dries unevenly in different locations. You might also be drying a species that you have less familiarity with, you could be drying a load of mixed species or boards with a high variation in the amount of sapwood and heartwood, or the lumber is thicker or more valuable. These are all good reasons to use more sample boards. If any of these situations apply and you choose to increase the number of sample boards you use, you could calculate your controlling MC by taking the average moisture content of the wettest half of your sample boards. (That’s the moisture content that the kiln schedules are based on.) In this example, since I assumed that the lumber is in a small kiln I am going to be conservative and use 22% as representative of the wettest half of the lumber. The next thing to do is to figure out which schedule to use and what conditions I should use at startup. Use the schedule for 4/4 red oak in Table 12 (Table 7.12, Drying Hardwood Lumber). Table 12. Kiln schedule for 4/4 and 5/4 red oak* ∗ Source: Drying Hardwood Lumber, Table 7.12. The first thing to do is to compare the MC of the wettest sample board MC (22%) to the MCs in the schedule. The 22% sample board is between 25% and 20%; it isn’t quite down to the 20% level yet, so you would enter the schedule for 4/4 red oak at the 25% line (see the box in Table 12) to identify the first set of prescribed conditions: a dry bulb of 130°F with a depression of 40° (a 90° F wet bulb) This corresponds to a 21% RH and an EMC of 3.9% (Appendix D). Since this is air-dried lumber we’re putting in the kiln, we ought to check to be sure that we aren’t 100PDF Image | HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNS

PDF Search Title:

HARDWOOD DRY KILN OPERATION A MANUAL FOR OPERATORS OF SMALL DRY KILNSOriginal File Name Searched:

FOR128.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |