PDF Publication Title:

Text from PDF Page: 055

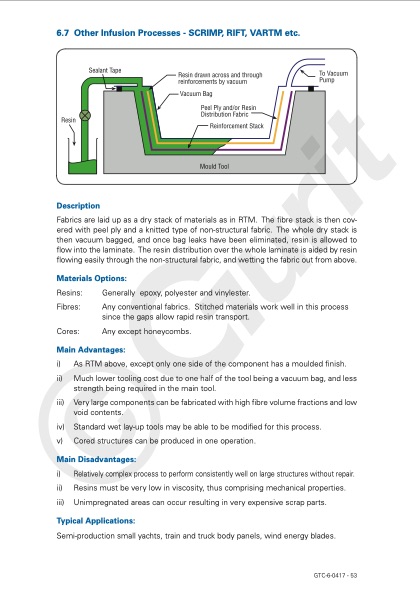

6.7 Other Infusion Processes - SCRIMP, RIFT, VARTM etc. Description Fabrics are laid up as a dry stack of materials as in RTM. The fibre stack is then cov- ered with peel ply and a knitted type of non-structural fabric. The whole dry stack is then vacuum bagged, and once bag leaks have been eliminated, resin is allowed to flow into the laminate. The resin distribution over the whole laminate is aided by resin flowing easily through the non-structural fabric, and wetting the fabric out from above. Materials Options: Resins: Fibres: Cores: Generally epoxy, polyester and vinylester. Any conventional fabrics. Stitched materials work well in this process since the gaps allow rapid resin transport. Any except honeycombs. Main Advantages: i) As RTM above, except only one side of the component has a moulded finish. ii) Much lower tooling cost due to one half of the tool being a vacuum bag, and less strength being required in the main tool. iii) Very large components can be fabricated with high fibre volume fractions and low void contents. iv) Standard wet lay-up tools may be able to be modified for this process. v) Cored structures can be produced in one operation. Main Disadvantages: i) Relatively complex process to perform consistently well on large structures without repair. ii) Resins must be very low in viscosity, thus comprising mechanical properties. iii) Unimpregnated areas can occur resulting in very expensive scrap parts. Typical Applications: Semi-production small yachts, train and truck body panels, wind energy blades. GTC-6-0417 - 53PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |