PDF Publication Title:

Text from PDF Page: 054

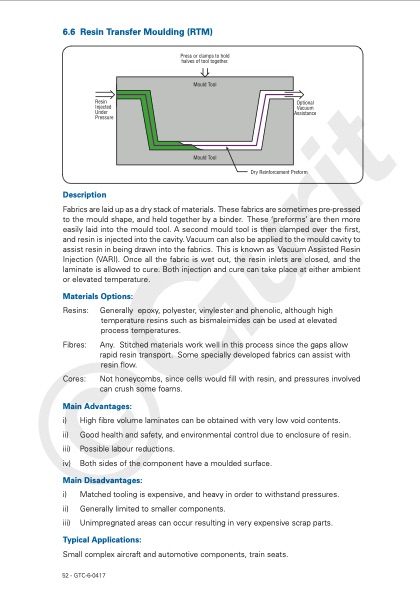

6.6 Resin Transfer Moulding (RTM) Description Fabrics are laid up as a dry stack of materials. These fabrics are sometimes pre-pressed to the mould shape, and held together by a binder. These ‘preforms’ are then more easily laid into the mould tool. A second mould tool is then clamped over the first, and resin is injected into the cavity. Vacuum can also be applied to the mould cavity to assist resin in being drawn into the fabrics. This is known as Vacuum Assisted Resin Injection (VARI). Once all the fabric is wet out, the resin inlets are closed, and the laminate is allowed to cure. Both injection and cure can take place at either ambient or elevated temperature. Materials Options: Resins: Fibres: Cores: Generally epoxy, polyester, vinylester and phenolic, although high temperature resins such as bismaleimides can be used at elevated process temperatures. Any. Stitched materials work well in this process since the gaps allow rapid resin transport. Some specially developed fabrics can assist with resin flow. Not honeycombs, since cells would fill with resin, and pressures involved can crush some foams. Main Advantages: i) High fibre volume laminates can be obtained with very low void contents. ii) Good health and safety, and environmental control due to enclosure of resin. iii) Possible labour reductions. iv) Both sides of the component have a moulded surface. Main Disadvantages: i) Matched tooling is expensive, and heavy in order to withstand pressures. ii) Generally limited to smaller components. iii) Unimpregnated areas can occur resulting in very expensive scrap parts. Typical Applications: Small complex aircraft and automotive components, train seats. 52 - GTC-6-0417PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |