PDF Publication Title:

Text from PDF Page: 050

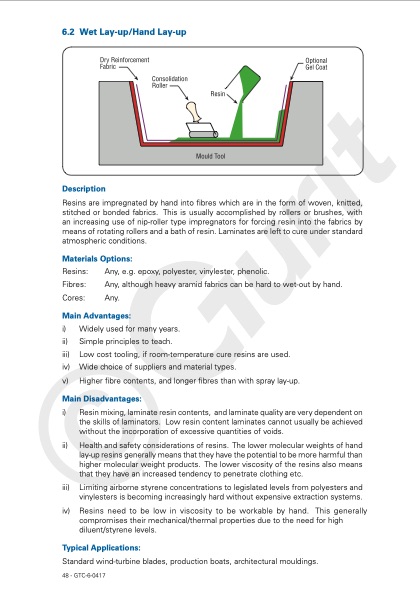

6.2 Wet Lay-up/Hand Lay-up Description Resins are impregnated by hand into fibres which are in the form of woven, knitted, stitched or bonded fabrics. This is usually accomplished by rollers or brushes, with an increasing use of nip-roller type impregnators for forcing resin into the fabrics by means of rotating rollers and a bath of resin. Laminates are left to cure under standard atmospheric conditions. Materials Options: Resins: Fibres: Cores: Any, e.g. epoxy, polyester, vinylester, phenolic. Any, although heavy aramid fabrics can be hard to wet-out by hand. Any. Main Advantages: i) Widely used for many years. ii) Simple principles to teach. iii) Low cost tooling, if room-temperature cure resins are used. iv) Wide choice of suppliers and material types. v) Higher fibre contents, and longer fibres than with spray lay-up. Main Disadvantages: i) Resin mixing, laminate resin contents, and laminate quality are very dependent on the skills of laminators. Low resin content laminates cannot usually be achieved without the incorporation of excessive quantities of voids. ii) Health and safety considerations of resins. The lower molecular weights of hand lay-up resins generally means that they have the potential to be more harmful than higher molecular weight products. The lower viscosity of the resins also means that they have an increased tendency to penetrate clothing etc. iii) Limiting airborne styrene concentrations to legislated levels from polyesters and vinylesters is becoming increasingly hard without expensive extraction systems. iv) Resins need to be low in viscosity to be workable by hand. This generally compromises their mechanical/thermal properties due to the need for high diluent/styrene levels. Typical Applications: Standard wind-turbine blades, production boats, architectural mouldings. 48 - GTC-6-0417PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |