PDF Publication Title:

Text from PDF Page: 049

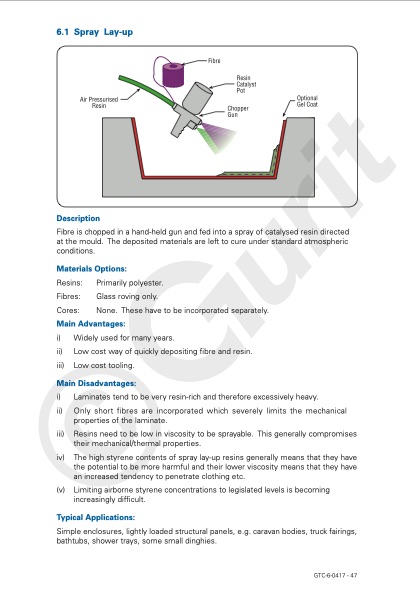

6.1 Spray Lay-up Description Fibre is chopped in a hand-held gun and fed into a spray of catalysed resin directed at the mould. The deposited materials are left to cure under standard atmospheric conditions. Materials Options: Resins: Fibres: Cores: Main Advantages: i) Widely used for many years. ii) Low cost way of quickly depositing fibre and resin. iii) Low cost tooling. Primarily polyester. Glass roving only. None. These have to be incorporated separately. Main Disadvantages: i) Laminates tend to be very resin-rich and therefore excessively heavy. ii) Only short fibres are incorporated which severely limits the mechanical properties of the laminate. iii) Resins need to be low in viscosity to be sprayable. This generally compromises their mechanical/thermal properties. iv) The high styrene contents of spray lay-up resins generally means that they have the potential to be more harmful and their lower viscosity means that they have an increased tendency to penetrate clothing etc. (v) Limiting airborne styrene concentrations to legislated levels is becoming increasingly difficult. Typical Applications: Simple enclosures, lightly loaded structural panels, e.g. caravan bodies, truck fairings, bathtubs, shower trays, some small dinghies. GTC-6-0417 - 47PDF Image | GUIDE TO COMPOSITES

PDF Search Title:

GUIDE TO COMPOSITESOriginal File Name Searched:

guide-to-composites.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |