PDF Publication Title:

Text from PDF Page: 004

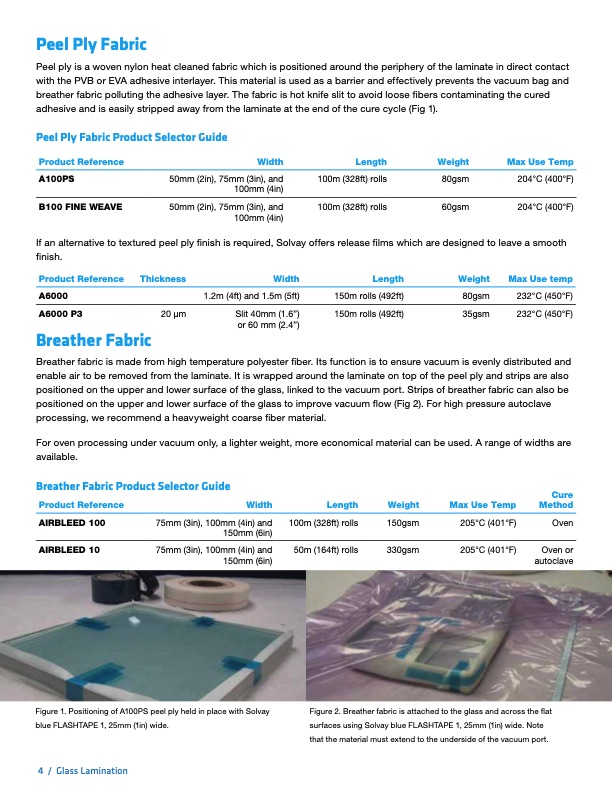

Peel Ply Fabric Peel ply is a woven nylon heat cleaned fabric which is positioned around the periphery of the laminate in direct contact with the PVB or EVA adhesive interlayer. This material is used as a barrier and effectively prevents the vacuum bag and breather fabric polluting the adhesive layer. The fabric is hot knife slit to avoid loose fibers contaminating the cured adhesive and is easily stripped away from the laminate at the end of the cure cycle (Fig 1). Peel Ply Fabric Product Selector Guide Product Reference A100PS B100 FINE WEAVE Width 50mm (2in), 75mm (3in), and 100mm (4in) 50mm (2in), 75mm (3in), and 100mm (4in) Length 100m (328ft) rolls 100m (328ft) rolls Weight 80gsm 60gsm Max Use Temp 204°C (400°F) 204°C (400°F) If an alternative to textured peel ply finish is required, Solvay offers release films which are designed to leave a smooth finish. Product Reference A6000 A6000 P3 Thickness 20 μm Width 1.2m (4ft) and 1.5m (5ft) Slit 40mm (1.6”) or 60 mm (2.4”) Length 150m rolls (492ft) 150m rolls (492ft) Weight 80gsm 35gsm Max Use temp 232°C (450°F) 232°C (450°F) Breather Fabric Breather fabric is made from high temperature polyester fiber. Its function is to ensure vacuum is evenly distributed and enable air to be removed from the laminate. It is wrapped around the laminate on top of the peel ply and strips are also positioned on the upper and lower surface of the glass, linked to the vacuum port. Strips of breather fabric can also be positioned on the upper and lower surface of the glass to improve vacuum flow (Fig 2). For high pressure autoclave processing, we recommend a heavyweight coarse fiber material. For oven processing under vacuum only, a lighter weight, more economical material can be used. A range of widths are available. Breather Fabric Product Selector Guide Cure Method Oven Oven or autoclave Product Reference AIRBLEED 100 AIRBLEED 10 Width 75mm (3in), 100mm (4in) and 150mm (6in) 75mm (3in), 100mm (4in) and 150mm (6in) Length 100m (328ft) rolls 50m (164ft) rolls Weight 150gsm 330gsm Max Use Temp 205°C (401°F) 205°C (401°F) Figure 1. Positioning of A100PS peel ply held in place with Solvay blue FLASHTAPE 1, 25mm (1in) wide. Figure 2. Breather fabric is attached to the glass and across the flat surfaces using Solvay blue FLASHTAPE 1, 25mm (1in) wide. Note that the material must extend to the underside of the vacuum port. 4 / Glass LaminationPDF Image | Glass Laminates COMPOSITE MATERIALS

PDF Search Title:

Glass Laminates COMPOSITE MATERIALSOriginal File Name Searched:

Composite-Glass-Laminates-Brochure.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |