PDF Publication Title:

Text from PDF Page: 003

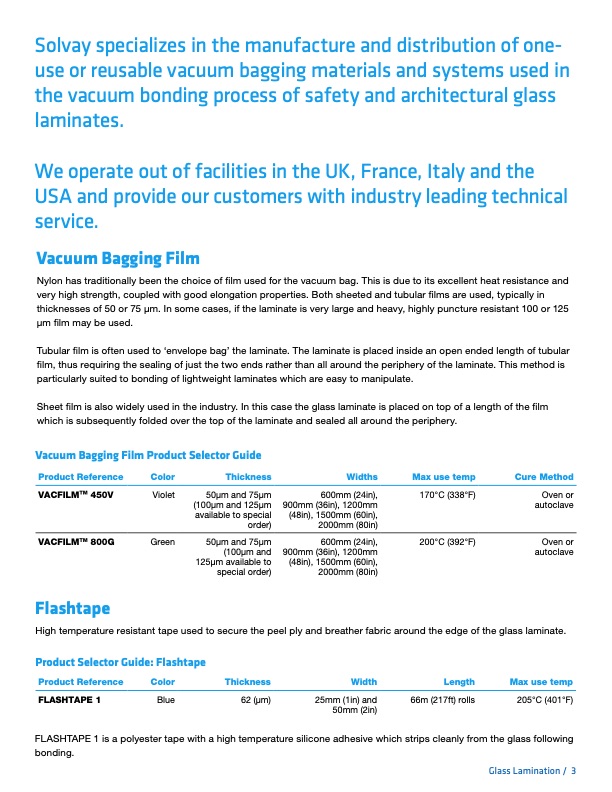

Solvay specializes in the manufacture and distribution of one- use or reusable vacuum bagging materials and systems used in the vacuum bonding process of safety and architectural glass laminates. We operate out of facilities in the UK, France, Italy and the USA and provide our customers with industry leading technical service. Vacuum Bagging Film Nylon has traditionally been the choice of film used for the vacuum bag. This is due to its excellent heat resistance and very high strength, coupled with good elongation properties. Both sheeted and tubular films are used, typically in thicknesses of 50 or 75 μm. In some cases, if the laminate is very large and heavy, highly puncture resistant 100 or 125 μm film may be used. Tubular film is often used to ‘envelope bag’ the laminate. The laminate is placed inside an open ended length of tubular film, thus requiring the sealing of just the two ends rather than all around the periphery of the laminate. This method is particularly suited to bonding of lightweight laminates which are easy to manipulate. Sheet film is also widely used in the industry. In this case the glass laminate is placed on top of a length of the film which is subsequently folded over the top of the laminate and sealed all around the periphery. Vacuum Bagging Film Product Selector Guide Product Reference VACFILMTM 450V VACFILMTM 800G Flashtape Color Violet Green Thickness 50μm and 75μm (100μm and 125μm available to special order) 50μm and 75μm (100μm and 125μm available to special order) Widths 600mm (24in), 900mm (36in), 1200mm (48in), 1500mm (60in), 2000mm (80in) 600mm (24in), 900mm (36in), 1200mm (48in), 1500mm (60in), 2000mm (80in) Max use temp 170°C (338°F) 200°C (392°F) Cure Method Oven or autoclave Oven or autoclave High temperature resistant tape used to secure the peel ply and breather fabric around the edge of the glass laminate. Product Selector Guide: Flashtape Product Reference Color Thickness Width Length Max use temp FLASHTAPE 1 Blue 62 (μm) 25mm (1in) and 66m (217ft) rolls 205°C (401°F) 50mm (2in) FLASHTAPE 1 is a polyester tape with a high temperature silicone adhesive which strips cleanly from the glass following bonding. Glass Lamination / 3PDF Image | Glass Laminates COMPOSITE MATERIALS

PDF Search Title:

Glass Laminates COMPOSITE MATERIALSOriginal File Name Searched:

Composite-Glass-Laminates-Brochure.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |