PDF Publication Title:

Text from PDF Page: 002

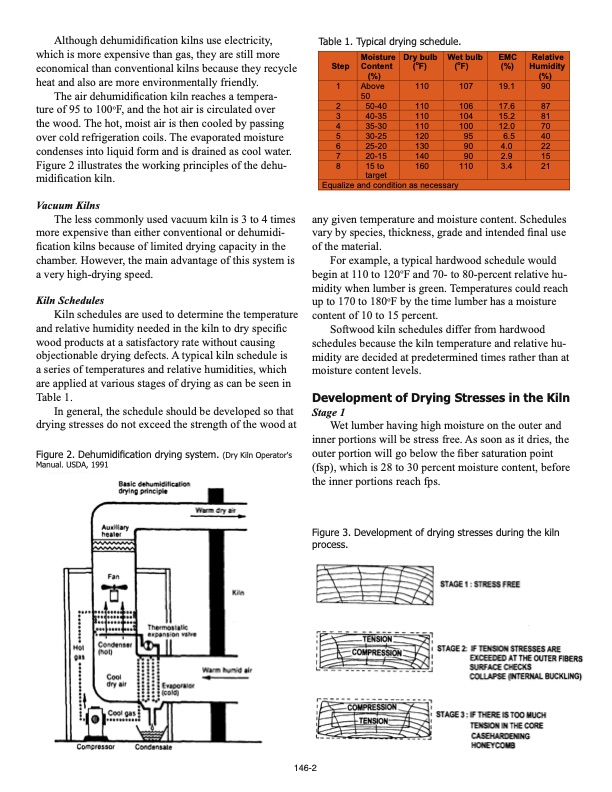

Although dehumidification kilns use electricity, which is more expensive than gas, they are still more economical than conventional kilns because they recycle heat and also are more environmentally friendly. The air dehumidification kiln reaches a tempera- ture of 95 to 100oF, and the hot air is circulated over the wood. The hot, moist air is then cooled by passing over cold refrigeration coils. The evaporated moisture condenses into liquid form and is drained as cool water. Figure 2 illustrates the working principles of the dehu- midification kiln. Vacuum Kilns The less commonly used vacuum kiln is 3 to 4 times more expensive than either conventional or dehumidi- fication kilns because of limited drying capacity in the chamber. However, the main advantage of this system is a very high-drying speed. Kiln Schedules Kiln schedules are used to determine the temperature and relative humidity needed in the kiln to dry specific wood products at a satisfactory rate without causing objectionable drying defects. A typical kiln schedule is a series of temperatures and relative humidities, which are applied at various stages of drying as can be seen in Table 1. In general, the schedule should be developed so that drying stresses do not exceed the strength of the wood at Figure 2. Dehumidification drying system. (Dry Kiln Operator's Manual. USDA, 1991 Table 1. Typical drying schedule. Moisture Step Content (%) Dry bulb (oF) Wet bulb (oF) EMC (%) Relative Humidity (%) 1 Above 110 107 19.1 90 50 2 50-40 110 106 17.6 87 3 40-35 110 104 15.2 81 4 35-30 110 100 12.0 70 5 30-25 120 95 6.5 40 6 25-20 130 90 4.0 22 7 20-15 140 90 2.9 15 8 15 to 160 110 3.4 21 target Equalize and condition as necessary any given temperature and moisture content. Schedules vary by species, thickness, grade and intended final use of the material. For example, a typical hardwood schedule would begin at 110 to 120oF and 70- to 80-percent relative hu- midity when lumber is green. Temperatures could reach up to 170 to 180oF by the time lumber has a moisture content of 10 to 15 percent. Softwood kiln schedules differ from hardwood schedules because the kiln temperature and relative hu- midity are decided at predetermined times rather than at moisture content levels. Development of Drying Stresses in the Kiln Stage 1 Wet lumber having high moisture on the outer and inner portions will be stress free. As soon as it dries, the outer portion will go below the fiber saturation point (fsp), which is 28 to 30 percent moisture content, before the inner portions reach fps. Figure 3. Development of drying stresses during the kiln process. 146-2PDF Image | Fundamental Aspects of Kiln Drying Lumber

PDF Search Title:

Fundamental Aspects of Kiln Drying LumberOriginal File Name Searched:

fundamental-aspects-of-kiln-drying-lumber-fapc-146.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |