PDF Publication Title:

Text from PDF Page: 001

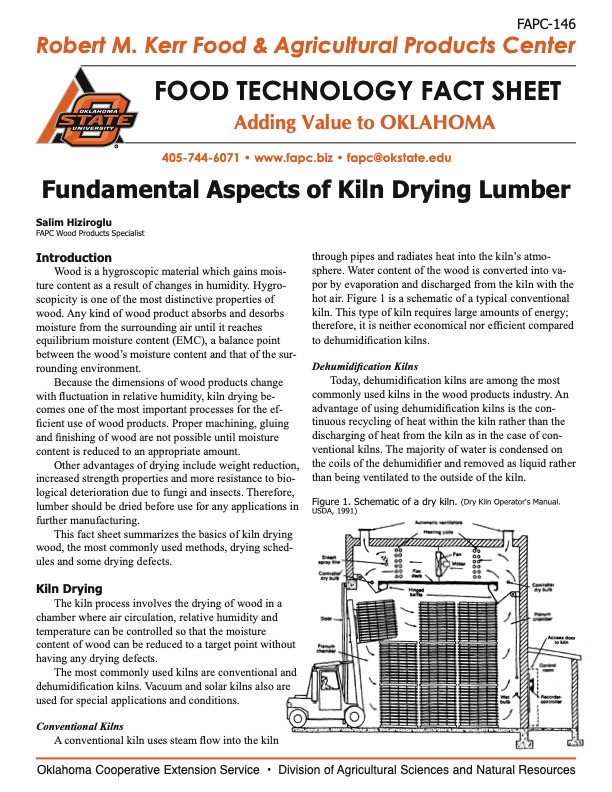

FAPC-146 Robert M. Kerr Food & Agricultural Products Center FOOD TECHNOLOGY FACT SHEET Adding Value to OKLAHOMA 405-744-6071 • www.fapc.biz • fapc@okstate.edu Fundamental Aspects of Kiln Drying Lumber Salim Hiziroglu FAPC Wood Products Specialist Introduction Wood is a hygroscopic material which gains mois- ture content as a result of changes in humidity. Hygro- scopicity is one of the most distinctive properties of wood. Any kind of wood product absorbs and desorbs moisture from the surrounding air until it reaches equilibrium moisture content (EMC), a balance point between the wood’s moisture content and that of the sur- rounding environment. Because the dimensions of wood products change with fluctuation in relative humidity, kiln drying be- comes one of the most important processes for the ef- ficient use of wood products. Proper machining, gluing and finishing of wood are not possible until moisture content is reduced to an appropriate amount. Other advantages of drying include weight reduction, increased strength properties and more resistance to bio- logical deterioration due to fungi and insects. Therefore, lumber should be dried before use for any applications in further manufacturing. This fact sheet summarizes the basics of kiln drying wood, the most commonly used methods, drying sched- ules and some drying defects. Kiln Drying The kiln process involves the drying of wood in a chamber where air circulation, relative humidity and temperature can be controlled so that the moisture content of wood can be reduced to a target point without having any drying defects. The most commonly used kilns are conventional and dehumidification kilns. Vacuum and solar kilns also are used for special applications and conditions. Conventional Kilns A conventional kiln uses steam flow into the kiln through pipes and radiates heat into the kiln’s atmo- sphere. Water content of the wood is converted into va- por by evaporation and discharged from the kiln with the hot air. Figure 1 is a schematic of a typical conventional kiln. This type of kiln requires large amounts of energy; therefore, it is neither economical nor efficient compared to dehumidification kilns. Dehumidification Kilns Today, dehumidification kilns are among the most commonly used kilns in the wood products industry. An advantage of using dehumidification kilns is the con- tinuous recycling of heat within the kiln rather than the discharging of heat from the kiln as in the case of con- ventional kilns. The majority of water is condensed on the coils of the dehumidifier and removed as liquid rather than being ventilated to the outside of the kiln. Figure 1. Schematic of a dry kiln. (Dry Kiln Operator's Manual. USDA, 1991) Oklahoma Cooperative Extension Service • Division of Agricultural Sciences and Natural ResourcesPDF Image | Fundamental Aspects of Kiln Drying Lumber

PDF Search Title:

Fundamental Aspects of Kiln Drying LumberOriginal File Name Searched:

fundamental-aspects-of-kiln-drying-lumber-fapc-146.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |