PDF Publication Title:

Text from PDF Page: 004

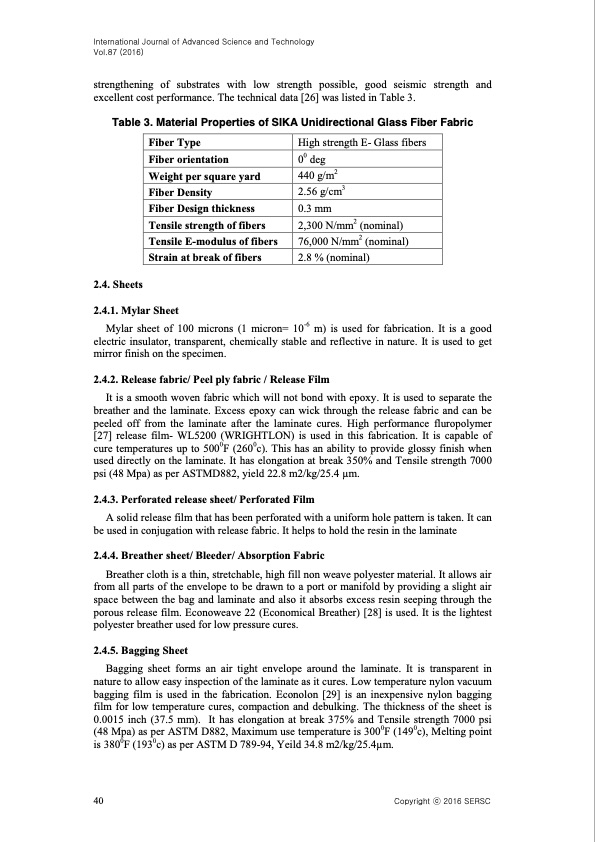

International Journal of Advanced Science and Technology Vol.87 (2016) strengthening of substrates with low strength possible, good seismic strength and excellent cost performance. The technical data [26] was listed in Table 3. Table 3. Material Properties of SIKA Unidirectional Glass Fiber Fabric Fiber Type Fiber orientation Weight per square yard Fiber Density Fiber Design thickness Tensile strength of fibers Tensile E-modulus of fibers Strain at break of fibers 2.4. Sheets 2.4.1. Mylar Sheet High strength E- Glass fibers 00 deg 440 g/m2 2.56 g/cm3 0.3 mm 2,300 N/mm2 (nominal) 76,000 N/mm2 (nominal) 2.8 % (nominal) Mylar sheet of 100 microns (1 micron= 10-6 m) is used for fabrication. It is a good electric insulator, transparent, chemically stable and reflective in nature. It is used to get mirror finish on the specimen. 2.4.2. Release fabric/ Peel ply fabric / Release Film It is a smooth woven fabric which will not bond with epoxy. It is used to separate the breather and the laminate. Excess epoxy can wick through the release fabric and can be peeled off from the laminate after the laminate cures. High performance fluropolymer [27] release film- WL5200 (WRIGHTLON) is used in this fabrication. It is capable of cure temperatures up to 5000F (2600c). This has an ability to provide glossy finish when used directly on the laminate. It has elongation at break 350% and Tensile strength 7000 psi (48 Mpa) as per ASTMD882, yield 22.8 m2/kg/25.4 μm. 2.4.3. Perforated release sheet/ Perforated Film A solid release film that has been perforated with a uniform hole pattern is taken. It can be used in conjugation with release fabric. It helps to hold the resin in the laminate 2.4.4. Breather sheet/ Bleeder/ Absorption Fabric Breather cloth is a thin, stretchable, high fill non weave polyester material. It allows air from all parts of the envelope to be drawn to a port or manifold by providing a slight air space between the bag and laminate and also it absorbs excess resin seeping through the porous release film. Econoweave 22 (Economical Breather) [28] is used. It is the lightest polyester breather used for low pressure cures. 2.4.5. Bagging Sheet Bagging sheet forms an air tight envelope around the laminate. It is transparent in nature to allow easy inspection of the laminate as it cures. Low temperature nylon vacuum bagging film is used in the fabrication. Econolon [29] is an inexpensive nylon bagging film for low temperature cures, compaction and debulking. The thickness of the sheet is 0.0015 inch (37.5 mm). It has elongation at break 375% and Tensile strength 7000 psi (48 Mpa) as per ASTM D882, Maximum use temperature is 3000F (1490c), Melting point is 3800F (1930c) as per ASTM D 789-94, Yeild 34.8 m2/kg/25.4μm. 40 Copyright c 2016 SERSCPDF Image | Fabrication of Continuous GFRP Composites using Vacuum Bag

PDF Search Title:

Fabrication of Continuous GFRP Composites using Vacuum BagOriginal File Name Searched:

GFRP-Composites-using-Vacuum-Bag.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |