PDF Publication Title:

Text from PDF Page: 003

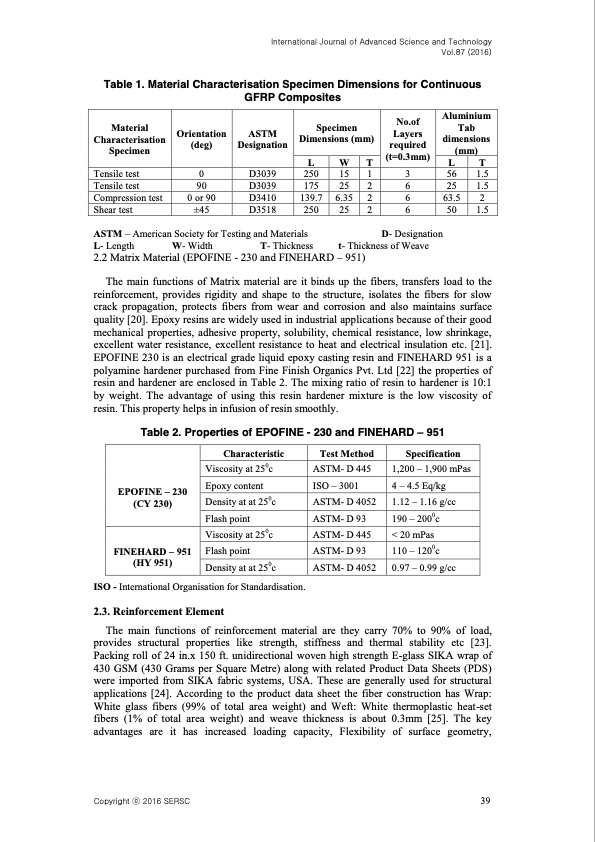

International Journal of Advanced Science and Technology Vol.87 (2016) Table 1. Material Characterisation Specimen Dimensions for Continuous GFRP Composites Material Characterisation Specimen Tensile test Tensile test Compression test Shear test Orientation (deg) 0 90 0 or 90 ±45 ASTM Designation D3039 D3039 D3410 D3518 Specimen Dimensions (mm) (t=0.3mm) (mm) LWT LT Aluminium Layers Tab 1 3 56 1.5 2 6 25 1.5 2 6 63.5 2 2 6 50 1.5 No.of required dimensions 250 15 175 25 139.7 6.35 250 25 ASTM – American Society for Testing and Materials L- Length W- Width T- Thickness 2.2 Matrix Material (EPOFINE - 230 and FINEHARD – 951) The main functions of Matrix material are it binds up the fibers, transfers load to the reinforcement, provides rigidity and shape to the structure, isolates the fibers for slow crack propagation, protects fibers from wear and corrosion and also maintains surface quality [20]. Epoxy resins are widely used in industrial applications because of their good mechanical properties, adhesive property, solubility, chemical resistance, low shrinkage, excellent water resistance, excellent resistance to heat and electrical insulation etc. [21]. EPOFINE 230 is an electrical grade liquid epoxy casting resin and FINEHARD 951 is a polyamine hardener purchased from Fine Finish Organics Pvt. Ltd [22] the properties of resin and hardener are enclosed in Table 2. The mixing ratio of resin to hardener is 10:1 by weight. The advantage of using this resin hardener mixture is the low viscosity of resin. This property helps in infusion of resin smoothly. Table 2. Properties of EPOFINE - 230 and FINEHARD – 951 D- Designation t- Thickness of Weave EPOFINE – 230 (CY 230) FINEHARD – 951 (HY 951) Characteristic Viscosity at 250c Epoxy content Density at at 250c Flash point Viscosity at 250c Flash point Density at at 250c Test Method ASTM- D 445 ISO – 3001 ASTM- D 4052 ASTM- D 93 ASTM- D 445 ASTM- D 93 ASTM- D 4052 Specification 1,200 – 1,900 mPas 4 – 4.5 Eq/kg 1.12 – 1.16 g/cc 190 – 2000c < 20 mPas 110 – 1200c 0.97 – 0.99 g/cc ISO - International Organisation for Standardisation. 2.3. Reinforcement Element The main functions of reinforcement material are they carry 70% to 90% of load, provides structural properties like strength, stiffness and thermal stability etc [23]. Packing roll of 24 in.x 150 ft. unidirectional woven high strength E-glass SIKA wrap of 430 GSM (430 Grams per Square Metre) along with related Product Data Sheets (PDS) were imported from SIKA fabric systems, USA. These are generally used for structural applications [24]. According to the product data sheet the fiber construction has Wrap: White glass fibers (99% of total area weight) and Weft: White thermoplastic heat-set fibers (1% of total area weight) and weave thickness is about 0.3mm [25]. The key advantages are it has increased loading capacity, Flexibility of surface geometry, Copyright c 2016 SERSC 39PDF Image | Fabrication of Continuous GFRP Composites using Vacuum Bag

PDF Search Title:

Fabrication of Continuous GFRP Composites using Vacuum BagOriginal File Name Searched:

GFRP-Composites-using-Vacuum-Bag.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |