PDF Publication Title:

Text from PDF Page: 113

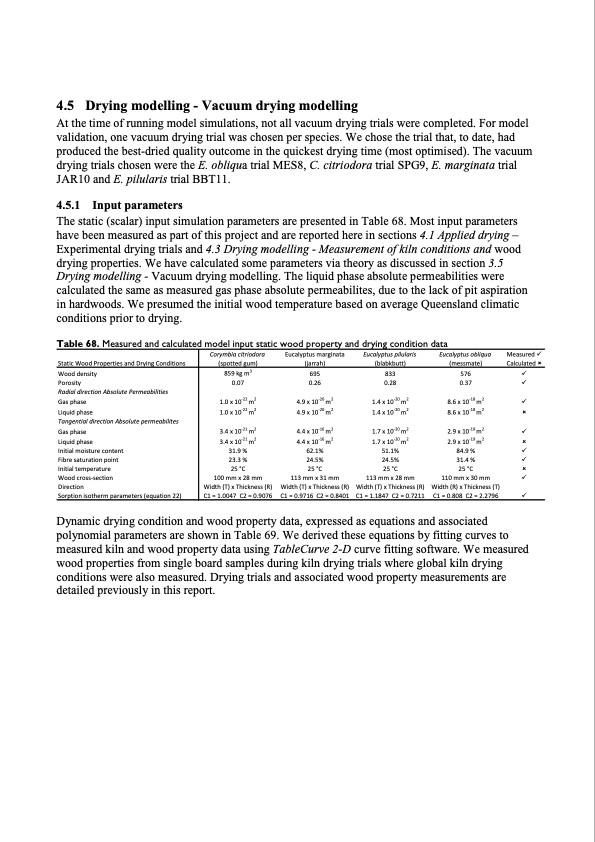

4.5 Drying modelling - Vacuum drying modelling At the time of running model simulations, not all vacuum drying trials were completed. For model validation, one vacuum drying trial was chosen per species. We chose the trial that, to date, had produced the best-dried quality outcome in the quickest drying time (most optimised). The vacuum drying trials chosen were the E. obliqua trial MES8, C. citriodora trial SPG9, E. marginata trial JAR10 and E. pilularis trial BBT11. 4.5.1 Input parameters The static (scalar) input simulation parameters are presented in Table 68. Most input parameters have been measured as part of this project and are reported here in sections 4.1 Applied drying – Experimental drying trials and 4.3 Drying modelling - Measurement of kiln conditions and wood drying properties. We have calculated some parameters via theory as discussed in section 3.5 Drying modelling - Vacuum drying modelling. The liquid phase absolute permeabilities were calculated the same as measured gas phase absolute permeabilites, due to the lack of pit aspiration in hardwoods. We presumed the initial wood temperature based on average Queensland climatic conditions prior to drying. Table 68. Measured and calculated model input static wood property and drying condition data Static Wood Properties and Drying Conditions Wood density Porosity Radial direction Absolute Permeabilities Gas phase Liquid phase Tangential direction Absolute permeabilites Gas phase Liquid phase Initial moisture content Fibre saturation point Initial temperature Woodcross-section Direction Sorption isotherm parameters (equation 22) Corymbia citriodora (spotted gum) 859 kg m3 0.07 1.0 x 10-22 m2 1.0 x 10-22 m2 3.4 x 10-21 m2 3.4 x 10-21 m2 31.9 % 23.3 % 25 °C Eucalyptus marginata (jarrah) 695 0.26 4.9 x 10-20 m2 4.9 x 10-20 m2 4.4 x 10-16 m2 4.4 x 10-16 m2 62.1% 24.5% 25 °C Eucalyptus pilularis (blabkbutt) 833 0.28 Eucalyptus obliqua (messmate) 576 0.37 8.6 x 10-18 m2 8.6 x 10-18 m2 2.9 x 10-19 m2 2.9 x 10-19 m2 84.9 % 31.4 % 25 °C Measured Calculated 25 °C 100mmx28mm 113mmx31mm 113mmx28mm 110mmx30mm Width (T) x Thickness (R) Width (T) x Thickness (R) Width (T) x Thickness (R) Width (R) x Thickness (T) C1 = 1.0047 C2 = 0.9076 C1 = 0.9716 C2 = 0.8401 C1 = 1.1847 C2 = 0.7211 C1 = 0.808 C2 = 2.2796 1.4 1.4 1.7 1.7 x 10-20 m2 x 10-20 m2 x 10-20 m2 x 10-20 m2 51.1% 24.5% Dynamic drying condition and wood property data, expressed as equations and associated polynomial parameters are shown in Table 69. We derived these equations by fitting curves to measured kiln and wood property data using TableCurve 2-D curve fitting software. We measured wood properties from single board samples during kiln drying trials where global kiln drying conditions were also measured. Drying trials and associated wood property measurements are detailed previously in this report.PDF Image | Evaluation of super-heated steam vacuum drying

PDF Search Title:

Evaluation of super-heated steam vacuum dryingOriginal File Name Searched:

PN08_2047_Vacuum_Drying_Reviewed_Report.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |