PDF Publication Title:

Text from PDF Page: 174

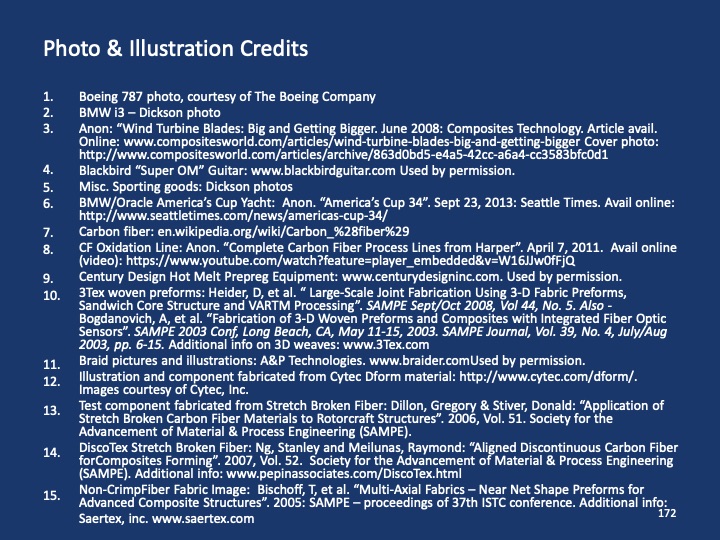

Photo & Illustration Credits 1. Boeing 787 photo, courtesy of The Boeing Company 2. BMW i3 – Dickson photo 3. Anon: “Wind Turbine Blades: Big and Getting Bigger. June 2008: Composites Technology. Article avail. Online: www.compositesworld.com/articles/wind-turbine-blades-big-and-getting-bigger Cover photo: http://www.compositesworld.com/articles/archive/863d0bd5-e4a5-42cc-a6a4-cc3583bfc0d1 4. Blackbird “Super OM” Guitar: www.blackbirdguitar.com Used by permission. 5. Misc. Sporting goods: Dickson photos 6. BMW/Oracle America’s Cup Yacht: Anon. “America’s Cup 34”. Sept 23, 2013: Seattle Times. Avail online: http://www.seattletimes.com/news/americas-cup-34/ 7. Carbon fiber: en.wikipedia.org/wiki/Carbon_%28fiber%29 CF Oxidation Line: Anon. “Complete Carbon Fiber Process Lines from Harper”. April 7, 2011. Avail online (video): https://www.youtube.com/watch?feature=player_embedded&v=W16JJw0fFjQ Century Design Hot Melt Prepreg Equipment: www.centurydesigninc.com. Used by permission. 3Tex woven preforms: Heider, D, et al. “ Large-Scale Joint Fabrication Using 3-D Fabric Preforms, Sandwich Core Structure and VARTM Processing”. SAMPE Sept/Oct 2008, Vol 44, No. 5. Also - Bogdanovich, A, et al. “Fabrication of 3-D Woven Preforms and Composites with Integrated Fiber Optic Sensors”. SAMPE 2003 Conf, Long Beach, CA, May 11-15, 2003. SAMPE Journal, Vol. 39, No. 4, July/Aug 2003, pp. 6-15. Additional info on 3D weaves: www.3Tex.com Braid pictures and illustrations: A&P Technologies. www.braider.comUsed by permission. Illustration and component fabricated from Cytec Dform material: http://www.cytec.com/dform/. Images courtesy of Cytec, Inc. Test component fabricated from Stretch Broken Fiber: Dillon, Gregory & Stiver, Donald: “Application of Stretch Broken Carbon Fiber Materials to Rotorcraft Structures”. 2006, Vol. 51. Society for the Advancement of Material & Process Engineering (SAMPE). DiscoTex Stretch Broken Fiber: Ng, Stanley and Meilunas, Raymond: “Aligned Discontinuous Carbon Fiber forComposites Forming”. 2007, Vol. 52. Society for the Advancement of Material & Process Engineering (SAMPE). Additional info: www.pepinassociates.com/DiscoTex.html 8. 9. 10. 11. 12. 13. 14. Non-CrimpFiber Fabric Image: Bischoff, T, et al. “Multi-Axial Fabrics – Near Net Shape Preforms for 15. Saertex, inc. www.saertex.com Advanced Composite Structures”. 2005: SAMPE – proceedings of 37th ISTC conference. Additional info: 172PDF Image | Composites 101 Workshop

PDF Search Title:

Composites 101 WorkshopOriginal File Name Searched:

AeroDef-2017-Composites-101-Workshop.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |