PDF Publication Title:

Text from PDF Page: 005

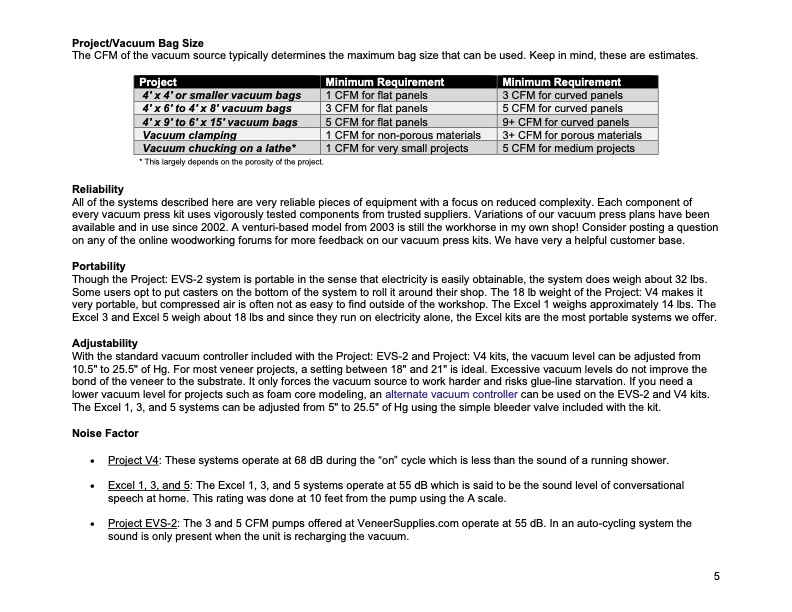

Project/Vacuum Bag Size The CFM of the vacuum source typically determines the maximum bag size that can be used. Keep in mind, these are estimates. Project Minimum Requirement Minimum Requirement 4' x 4' or smaller vacuum bags 1 CFM for flat panels 3 CFM for curved panels 4' x 6' to 4' x 8' vacuum bags 3 CFM for flat panels 5 CFM for curved panels 4' x 9' to 6' x 15' vacuum bags 5 CFM for flat panels 9+ CFM for curved panels Vacuum clamping 1 CFM for non-porous materials 3+ CFM for porous materials Vacuum chucking on a lathe* 1 CFM for very small projects 5 CFM for medium projects * This largely depends on the porosity of the project. Reliability All of the systems described here are very reliable pieces of equipment with a focus on reduced complexity. Each component of every vacuum press kit uses vigorously tested components from trusted suppliers. Variations of our vacuum press plans have been available and in use since 2002. A venturi-based model from 2003 is still the workhorse in my own shop! Consider posting a question on any of the online woodworking forums for more feedback on our vacuum press kits. We have very a helpful customer base. Portability Though the Project: EVS-2 system is portable in the sense that electricity is easily obtainable, the system does weigh about 32 lbs. Some users opt to put casters on the bottom of the system to roll it around their shop. The 18 lb weight of the Project: V4 makes it very portable, but compressed air is often not as easy to find outside of the workshop. The Excel 1 weighs approximately 14 lbs. The Excel 3 and Excel 5 weigh about 18 lbs and since they run on electricity alone, the Excel kits are the most portable systems we offer. Adjustability With the standard vacuum controller included with the Project: EVS-2 and Project: V4 kits, the vacuum level can be adjusted from 10.5" to 25.5" of Hg. For most veneer projects, a setting between 18" and 21" is ideal. Excessive vacuum levels do not improve the bond of the veneer to the substrate. It only forces the vacuum source to work harder and risks glue-line starvation. If you need a lower vacuum level for projects such as foam core modeling, an alternate vacuum controller can be used on the EVS-2 and V4 kits. The Excel 1, 3, and 5 systems can be adjusted from 5" to 25.5" of Hg using the simple bleeder valve included with the kit. Noise Factor • Project V4: These systems operate at 68 dB during the “on” cycle which is less than the sound of a running shower. • Excel 1, 3, and 5: The Excel 1, 3, and 5 systems operate at 55 dB which is said to be the sound level of conversational speech at home. This rating was done at 10 feet from the pump using the A scale. • Project EVS-2: The 3 and 5 CFM pumps offered at VeneerSupplies.com operate at 55 dB. In an auto-cycling system the sound is only present when the unit is recharging the vacuum. 5PDF Image | Composite Curing and Vacuum Bagging Ovens and Controls for Aerospace

PDF Search Title:

Composite Curing and Vacuum Bagging Ovens and Controls for AerospaceOriginal File Name Searched:

vacuumpresschart.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |