PDF Publication Title:

Text from PDF Page: 003

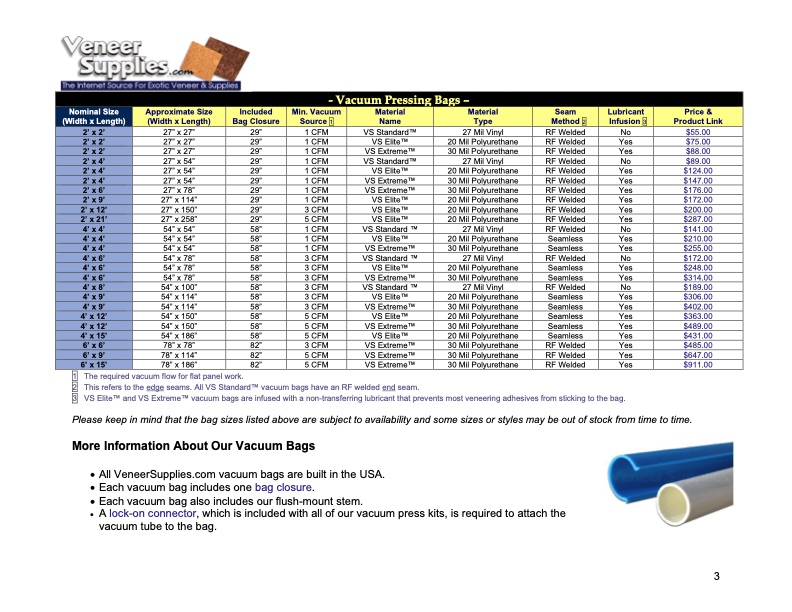

- Vacuum Pressing Bags – Nominal Size (Width x Length) Approximate Size (Width x Length) Included Bag Closure Min. Vacuum Source 1 Material Name Material Type Seam Method 2 Lubricant Infusion 3 Price & Product Link 2’ x 2’ 2’ x 2’ 2’ x 2’ 2’ x 4’ 2’ x 4’ 2’ x 4’ 2’ x 6’ 2’ x 9’ 2’ x 12’ 2’ x 21’ 4’ x 4’ 4’ x 4’ 4’ x 4’ 4’ x 6’ 4’ x 6’ 4’ x 6’ 4’ x 8’ 4’ x 9’ 4’ x 9’ 4’ x 12’ 4’ x 12’ 4’ x 15’ 6’ x 6’ 6’ x 9’ 6’ x 15’ 27” x 27” 29” 27” x 27” 29” 27” x 27” 29” 27” x 54” 29” 27” x 54” 29” 27” x 54” 29” 27” x 78” 29” 27” x 114” 29” 27” x 150” 29” 27” x 258” 29” 54” x 54” 58” 54” x 54” 58” 54” x 54” 58” 54” x 78” 58” 54” x 78” 58” 54” x 78” 58” 54” x 100” 58” 54” x 114” 58” 54” x 114” 58” 54” x 150” 58” 54” x 150” 58” 54” x 186” 58” 78” x 78” 82” 78” x 114” 82” 78” x 186” 82” 1 CFM 1 CFM 1 CFM 1 CFM 1 CFM 1 CFM 1 CFM 1 CFM 3 CFM 5 CFM 1 CFM 1 CFM 1 CFM 3 CFM 3 CFM 3 CFM 3 CFM 3 CFM 3 CFM 5 CFM 5 CFM 5 CFM 3 CFM 5 CFM 5 CFM VS StandardTM VS EliteTM VS ExtremeTM VS StandardTM VS EliteTM VS ExtremeTM VS ExtremeTM VS EliteTM VS EliteTM VS EliteTM VS Standard TM VS EliteTM VS ExtremeTM VS Standard TM VS EliteTM VS ExtremeTM VS Standard TM VS EliteTM VS ExtremeTM VS EliteTM VS ExtremeTM VS EliteTM VS ExtremeTM VS ExtremeTM VS ExtremeTM 27 Mil Vinyl 20 Mil Polyurethane 30 Mil Polyurethane 27 Mil Vinyl 20 Mil Polyurethane 30 Mil Polyurethane 30 Mil Polyurethane 20 Mil Polyurethane 20 Mil Polyurethane 20 Mil Polyurethane 27 Mil Vinyl 20 Mil Polyurethane 30 Mil Polyurethane 27 Mil Vinyl 20 Mil Polyurethane 30 Mil Polyurethane 27 Mil Vinyl 20 Mil Polyurethane 30 Mil Polyurethane 20 Mil Polyurethane 30 Mil Polyurethane 20 Mil Polyurethane 30 Mil Polyurethane 30 Mil Polyurethane 30 Mil Polyurethane RF Welded No RF Welded Yes RF Welded Yes RF Welded No RF Welded Yes RF Welded Yes RF Welded Yes RF Welded Yes RF Welded Yes RF Welded Yes RF Welded No Seamless Yes Seamless Yes RF Welded No Seamless Yes Seamless Yes RF Welded No Seamless Yes Seamless Yes Seamless Yes Seamless Yes Seamless Yes RF Welded Yes RF Welded Yes RF Welded Yes $55.00 $75.00 $88.00 $89.00 $124.00 $147.00 $176.00 $172.00 $200.00 $287.00 $141.00 $210.00 $255.00 $172.00 $248.00 $314.00 $189.00 $306.00 $402.00 $363.00 $489.00 $431.00 $485.00 $647.00 $911.00 1 The required vacuum flow for flat panel work. 2 This refers to the edge seams. All VS StandardTM vacuum bags have an RF welded end seam. 3 VS EliteTM and VS ExtremeTM vacuum bags are infused with a non-transferring lubricant that prevents most veneering adhesives from sticking to the bag. Please keep in mind that the bag sizes listed above are subject to availability and some sizes or styles may be out of stock from time to time. More Information About Our Vacuum Bags • All VeneerSupplies.com vacuum bags are built in the USA. • Each vacuum bag includes one bag closure. • Each vacuum bag also includes our flush-mount stem. • A lock-on connector, which is included with all of our vacuum press kits, is required to attach the vacuum tube to the bag. 3PDF Image | Composite Curing and Vacuum Bagging Ovens and Controls for Aerospace

PDF Search Title:

Composite Curing and Vacuum Bagging Ovens and Controls for AerospaceOriginal File Name Searched:

vacuumpresschart.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |