PDF Publication Title:

Text from PDF Page: 002

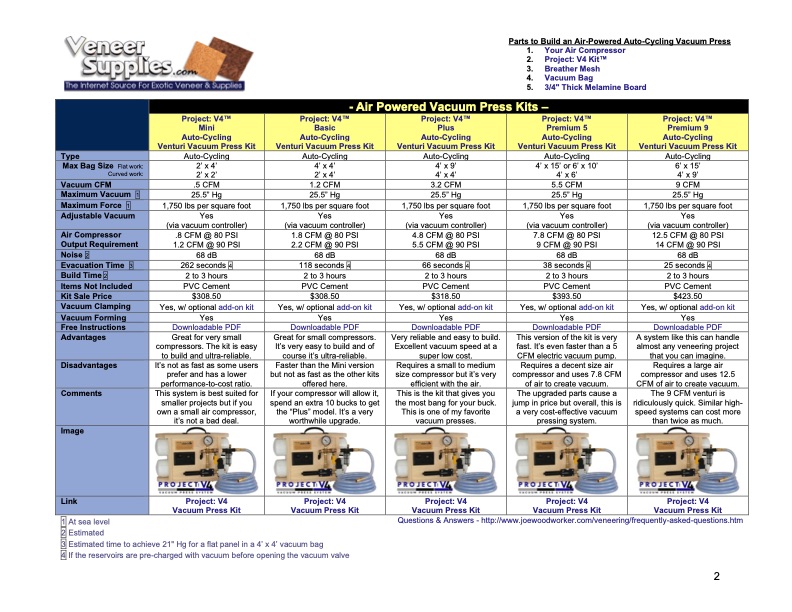

- Air Powered Vacuum Press Kits – Project: V4TM Mini Auto-Cycling Venturi Vacuum Press Kit Auto-Cycling 2’ x 4’ 2’ x 2’ .5 CFM 25.5” Hg 1,750 lbs per square foot Yes (via vacuum controller) .8 CFM @ 80 PSI 1.2 CFM @ 90 PSI 68 dB 262 seconds 4 2 to 3 hours PVC Cement $308.50 Yes, w/ optional add-on kit Yes Downloadable PDF Great for very small compressors. The kit is easy to build and ultra-reliable. It’s not as fast as some users prefer and has a lower performance-to-cost ratio. Auto-Cycling 4’ x 4’ 2’ x 4’ 1.2 CFM 25.5” Hg 1,750 lbs per square foot Yes (via vacuum controller) 1.8 CFM @ 80 PSI 2.2 CFM @ 90 PSI 68 dB 118 seconds 4 2 to 3 hours PVC Cement $308.50 Yes, w/ optional add-on kit Yes Downloadable PDF Great for small compressors. It’s very easy to build and of course it’s ultra-reliable. Faster than the Mini version but not as fast as the other kits offered here. Auto-Cycling 4’ x 9’ 4’ x 4’ 3.2 CFM 25.5” Hg 1,750 lbs per square foot Yes (via vacuum controller) 4.8 CFM @ 80 PSI 5.5 CFM @ 90 PSI 68 dB 66 seconds 4 2 to 3 hours PVC Cement $318.50 Yes, w/ optional add-on kit Yes Downloadable PDF Very reliable and easy to build. Excellent vacuum speed at a super low cost. Requires a small to medium size compressor but it’s very efficient with the air. Auto-Cycling 4’ x 15’ or 6’ x 10’ 4’ x 6’ 5.5 CFM 25.5” Hg 1,750 lbs per square foot Yes (via vacuum controller) 7.8 CFM @ 80 PSI 9 CFM @ 90 PSI 68 dB 38 seconds 4 2 to 3 hours PVC Cement $393.50 Yes, w/ optional add-on kit Yes Downloadable PDF This version of the kit is very fast. It’s even faster than a 5 CFM electric vacuum pump. Requires a decent size air compressor and uses 7.8 CFM of air to create vacuum. Auto-Cycling 6’ x 15’ 4’ x 9’ 9 CFM 25.5” Hg 1,750 lbs per square foot Yes (via vacuum controller) 12.5 CFM @ 80 PSI 14 CFM @ 90 PSI 68 dB 25 seconds 4 2 to 3 hours PVC Cement $423.50 Yes, w/ optional add-on kit Yes Downloadable PDF A system like this can handle almost any veneering project that you can imagine. Requires a large air compressor and uses 12.5 CFM of air to create vacuum. Project: V4TM Basic Auto-Cycling Venturi Vacuum Press Kit Project: V4TM Plus Auto-Cycling Venturi Vacuum Press Kit Parts to Build an Air-Powered Auto-Cycling Vacuum Press 1. 2. 3. 4. 5. Your Air Compressor Project: V4 KitTM Breather Mesh Vacuum Bag 3/4" Thick Melamine Board Project: V4TM Premium 5 Auto-Cycling Venturi Vacuum Press Kit Project: V4TM Premium 9 Auto-Cycling Venturi Vacuum Press Kit Type Max Bag Size Flat work: Curved work: Vacuum CFM MaximumVacuum 1 Maximum Force 1 Adjustable Vacuum Air Compressor Output Requirement Noise 2 EvacuationTime 3 Build Time 2 Items Not Included Kit Sale Price Vacuum Clamping Vacuum Forming Free Instructions Advantages Disadvantages This system is best suited for smaller projects but if you own a small air compressor, it’s not a bad deal. If your compressor will allow it, spend an extra 10 bucks to get the “Plus” model. It’s a very worthwhile upgrade. This is the kit that gives you the most bang for your buck. This is one of my favorite vacuum presses. The upgraded parts cause a jump in price but overall, this is a very cost-effective vacuum pressing system. The 9 CFM venturi is ridiculously quick. Similar high- speed systems can cost more than twice as much. Comments Image Link Project: V4 Vacuum Press Kit Project: V4 Vacuum Press Kit Project: V4 Vacuum Press Kit Project: V4 Vacuum Press Kit Project: V4 Vacuum Press Kit 1 At sea level 2 Estimated 3 Estimated time to achieve 21" Hg for a flat panel in a 4’ x 4’ vacuum bag 4 If the reservoirs are pre-charged with vacuum before opening the vacuum valve Questions & Answers - http://www.joewoodworker.com/veneering/frequently-asked-questions.htm 2PDF Image | Composite Curing and Vacuum Bagging Ovens and Controls for Aerospace

PDF Search Title:

Composite Curing and Vacuum Bagging Ovens and Controls for AerospaceOriginal File Name Searched:

vacuumpresschart.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |