PDF Publication Title:

Text from PDF Page: 003

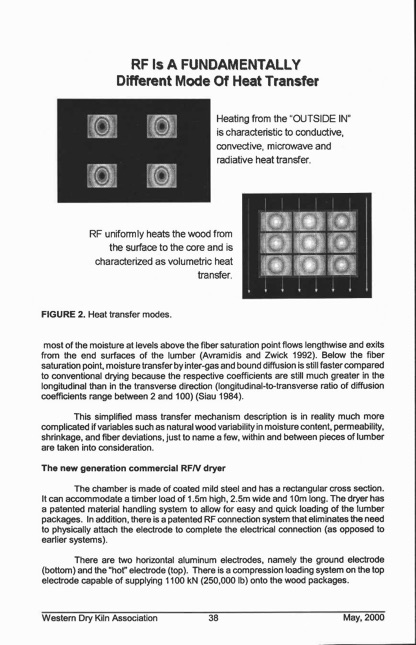

RF Is A FUNDAMENTALLY Different Mode Of Heat Transfer Heating from the "OUTSIDE IN" is characteristic to conductive, convective, microwave and radiative heat transfer. RF uniformly heats the wood from the surface to the core and is characterized as volumetric heat transfer. FIGURE 2. Heat transfer modes. most of the moisture at levels above the fiber saturation point flows lengthwise and exits from the end surfaces of the lumber (Avramidis and Zwick 1992). Below the fiber saturation point, moisture transfer by inter-gas and bound diffusion is still faster compared to conventional drying because the respective coefficients are still much greater in the longitudinal than in the transverse direction (longitudinal-to-transverse ratio of diffusion coefficients range between 2 and 100) (Siau 1984). This simplified mass transfer mechanism description is in reality much more complicated if variables such as natural wood variability in moisture content, permeability, shrinkage, and fiber deviations, just to name a few, within and between pieces of lumber are taken into consideration. The new generation commercial RFN dryer The chamber is made of coated mild steel and has a rectangular cross section. It can accommodate a timber load of 1.5m high, 2.5m wide and 10m long. The dryer has a patented material handling system to allow for easy and quick loading of the lumber packages. In addition, there is a patented RF connection system that eliminates the need to physically attach the electrode to complete the electrical connection (as opposed to earlier systems). There are two horizontal aluminum electrodes, namely the ground electrode (bottom) and the "hot" electrode (top). There is a compression loading system on the top electrode capable of supplying 1100 kN (250,000 lb) onto the wood packages. Western Dry Kiln Association� 38� May, 2000PDF Image | COMMERCIAL RFV KILN DRYING

PDF Search Title:

COMMERCIAL RFV KILN DRYINGOriginal File Name Searched:

Commercial_RFV_ocr.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |