PDF Publication Title:

Text from PDF Page: 009

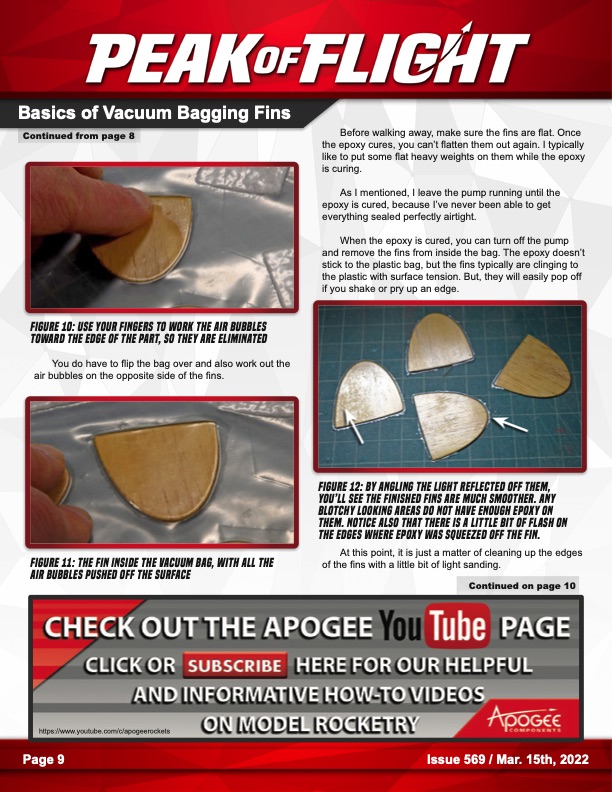

Continued from page 8 Continued on page 10 https://www.youtube.com/c/apogeerockets Basics of Vacuum Bagging Fins Figure 10: Use your fingers to work the air bubbles toward the edge of the part, so they are eliminated You do have to flip the bag over and also work out the air bubbles on the opposite side of the fins. Figure 11: The fin inside the vacuum bag, with all the air bubbles pushed off the surface Figure 12: By angling the light reflected off them, you’ll see the finished fins are much smoother. Any blotchy looking areas do not have enough epoxy on them. Notice also that there is a little bit of flash on the edges where epoxy was squeezed off the fin. At this point, it is just a matter of cleaning up the edges of the fins with a little bit of light sanding. Page 9 Issue 569 / Mar. 15th, 2022 Before walking away, make sure the fins are flat. Once the epoxy cures, you can’t flatten them out again. I typically like to put some flat heavy weights on them while the epoxy is curing. As I mentioned, I leave the pump running until the epoxy is cured, because I’ve never been able to get everything sealed perfectly airtight. When the epoxy is cured, you can turn off the pump and remove the fins from inside the bag. The epoxy doesn’t stick to the plastic bag, but the fins typically are clinging to the plastic with surface tension. But, they will easily pop off if you shake or pry up an edge.PDF Image | Basics of Vacuum Bagging Fins

PDF Search Title:

Basics of Vacuum Bagging FinsOriginal File Name Searched:

Newsletter569.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |