PDF Publication Title:

Text from PDF Page: 198

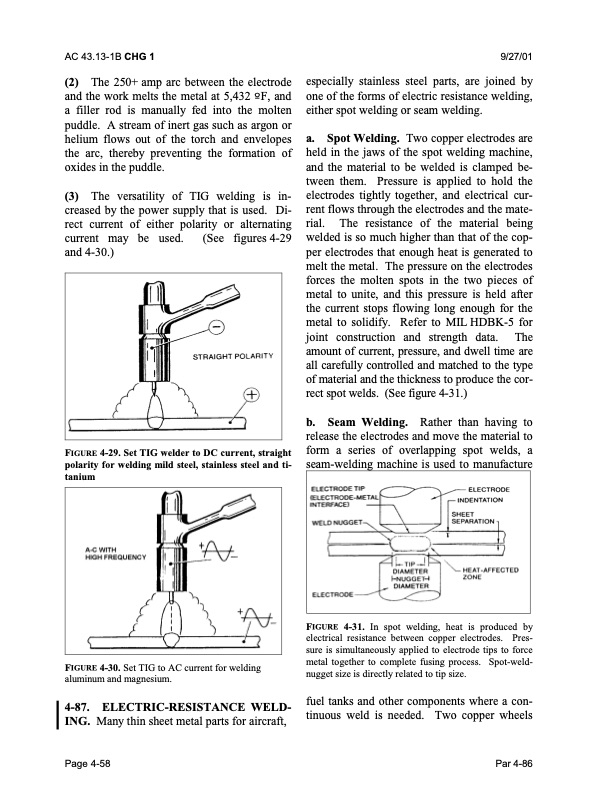

AC 43.13-1B CHG 1 9/27/01 (2) The 250+ amp arc between the electrode and the work melts the metal at 5,432oF, and a filler rod is manually fed into the molten puddle. A stream of inert gas such as argon or helium flows out of the torch and envelopes the arc, thereby preventing the formation of oxides in the puddle. (3) The versatility of TIG welding is in creased by the power supply that is used. Di rect current of either polarity or alternating especially stainless steel parts, are joined by one of the forms of electric resistance welding, either spot welding or seam welding. a. Spot Welding. Two copper electrodes are held in the jaws of the spot welding machine, and the material to be welded is clamped be tween them. Pressure is applied to hold the electrodes tightly together, and electrical cur rent flows through the electrodes and the mate rial. The resistance of the material being welded is so much higher than that of the cop per electrodes that enough heat is generated to melt the metal. The pressure on the electrodes forces the molten spots in the two pieces of metal to unite, and this pressure is held after the current stops flowing long enough for the metal to solidify. Refer to MIL HDBK-5 for joint construction and strength data. The amount of current, pressure, and dwell time are all carefully controlled and matched to the type of material and the thickness to produce the cor rect spot welds. (See figure 4-31.) b. Seam Welding. Rather than having to release the electrodes and move the material to form a series of overlapping spot welds, a seam-welding machine is used to manufacture FIGURE 4-31. In spot welding, heat is produced by electrical resistance between copper electrodes. Pres sure is simultaneously applied to electrode tips to force metal together to complete fusing process. Spot-weld nugget size is directly related to tip size. fuel tanks and other components where a con tinuous weld is needed. Two copper wheels current may be used. (See and 4-30.) figures 4-29 FIGURE 4-29. Set TIG welder to DC current, straight polarity for welding mild steel, stainless steel and ti tanium FIGURE 4-30. Set TIG to AC current for welding aluminum and magnesium. 4-87. ELECTRIC-RESISTANCE WELD ING. Many thin sheet metal parts for aircraft, Page 4-58 Par 4-86PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |