PDF Publication Title:

Text from PDF Page: 197

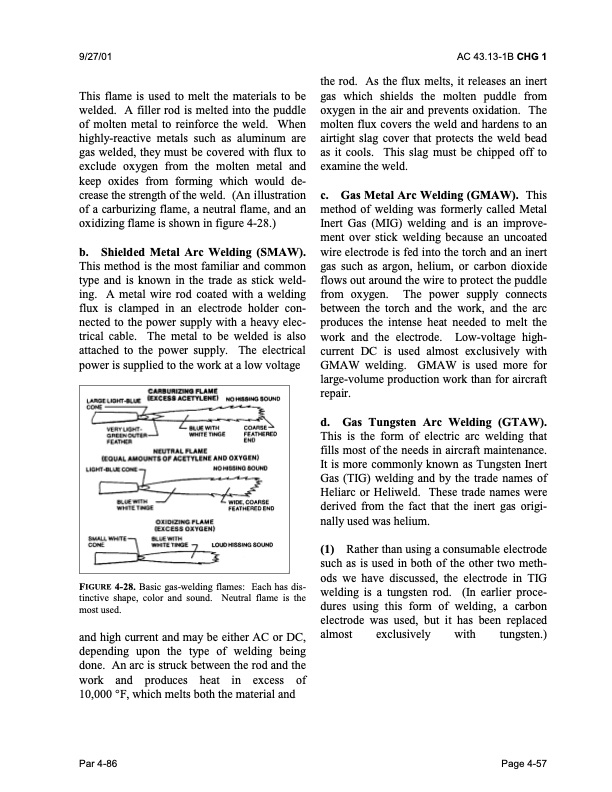

9/27/01 AC 43.13-1B CHG 1 This flame is used to melt the materials to be welded. A filler rod is melted into the puddle of molten metal to reinforce the weld. When highly-reactive metals such as aluminum are gas welded, they must be covered with flux to exclude oxygen from the molten metal and keep oxides from forming which would de crease the strength of the weld. (An illustration of a carburizing flame, a neutral flame, and an oxidizing flame is shown in figure 4-28.) b. Shielded Metal Arc Welding (SMAW). This method is the most familiar and common type and is known in the trade as stick weld ing. A metal wire rod coated with a welding flux is clamped in an electrode holder con nected to the power supply with a heavy elec trical cable. The metal to be welded is also attached to the power supply. The electrical power is supplied to the work at a low voltage FIGURE 4-28. Basic gas-welding flames: Each has dis tinctive shape, color and sound. Neutral flame is the most used. and high current and may be either AC or DC, depending upon the type of welding being done. An arc is struck between the rod and the work and produces heat in excess of 10,000 °F, which melts both the material and the rod. As the flux melts, it releases an inert gas which shields the molten puddle from oxygen in the air and prevents oxidation. The molten flux covers the weld and hardens to an airtight slag cover that protects the weld bead as it cools. This slag must be chipped off to examine the weld. c. Gas Metal Arc Welding (GMAW). This method of welding was formerly called Metal Inert Gas (MIG) welding and is an improve ment over stick welding because an uncoated wire electrode is fed into the torch and an inert gas such as argon, helium, or carbon dioxide flows out around the wire to protect the puddle from oxygen. The power supply connects between the torch and the work, and the arc produces the intense heat needed to melt the work and the electrode. Low-voltage high- current DC is used almost exclusively with GMAW welding. GMAW is used more for large-volume production work than for aircraft repair. d. Gas Tungsten Arc Welding (GTAW). This is the form of electric arc welding that fills most of the needs in aircraft maintenance. It is more commonly known as Tungsten Inert Gas (TIG) welding and by the trade names of Heliarc or Heliweld. These trade names were derived from the fact that the inert gas origi nally used was helium. (1) Rather than using a consumable electrode such as is used in both of the other two meth ods we have discussed, the electrode in TIG welding is a tungsten rod. (In earlier proce dures using this form of welding, a carbon electrode was used, but it has been replaced Par 4-86 Page 4-57 almost exclusively with tungsten.)PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |