PDF Publication Title:

Text from PDF Page: 178

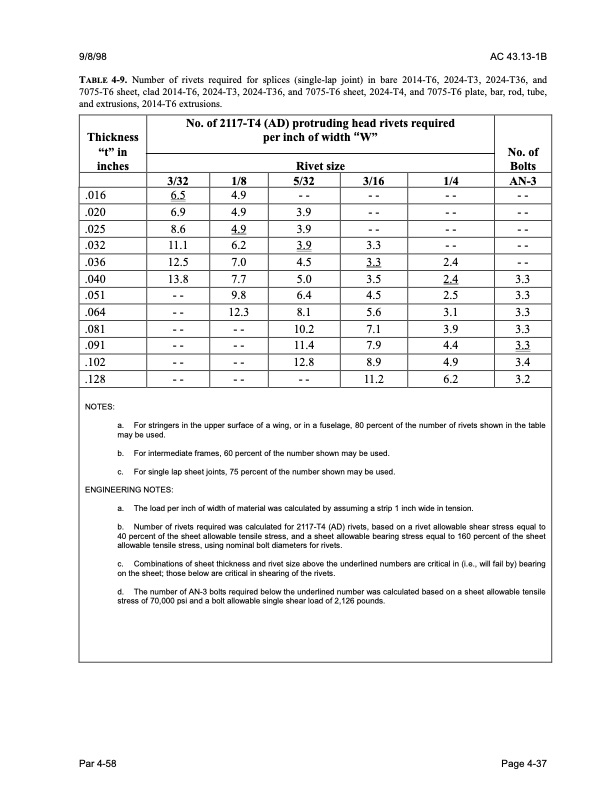

9/8/98 AC 43.13-1B TABLE 4-9. Number of rivets required for splices (single-lap joint) in bare 2014-T6, 2024-T3, 2024-T36, and 7075-T6 sheet, clad 2014-T6, 2024-T3, 2024-T36, and 7075-T6 sheet, 2024-T4, and 7075-T6 plate, bar, rod, tube, and extrusions, 2014-T6 extrusions. Thickness “t” in inches No. of 2117-T4 (AD) protruding head rivets required per inch of width “W” No. of Bolts Rivet size 3/32 1/8 5/32 3/16 1/4 AN-3 .016 .020 .025 .032 .036 .040 .051 .064 .081 .091 .102 .128 6.5 4.9 6.9 4.9 8.6 4.9 11.1 6.2 12.5 7.0 13.8 7.7 - 9.8 - 12.3 - - 10.2 - - 11.4 - - 12.8 - - - 11.2 - - - - - - - - - - - - 2.4 - 2.4 3.3 2.5 3.3 3.1 3.3 3.9 3.3 4.4 3.3 4.9 3.4 6.2 3.2 3.9 3.9 3.9 4.5 5.0 6.4 8.1 3.3 3.3 3.5 4.5 5.6 7.1 7.9 8.9 NOTES: c. For single lap sheet joints, 75 percent of the number shown may be used. ENGINEERING NOTES: a. The load per inch of width of material was calculated by assuming a strip 1 inch wide in tension. b. Number of rivets required was calculated for 2117-T4 (AD) rivets, based on a rivet allowable shear stress equal to 40 percent of the sheet allowable tensile stress, and a sheet allowable bearing stress equal to 160 percent of the sheet allowable tensile stress, using nominal bolt diameters for rivets. c. Combinations of sheet thickness and rivet size above the underlined numbers are critical in (i.e., will fail by) bearing on the sheet; those below are critical in shearing of the rivets. d. The number of AN-3 bolts required below the underlined number was calculated based on a sheet allowable tensile stress of 70,000 psi and a bolt allowable single shear load of 2,126 pounds. a. For stringers in the upper surface of a wing, or in a fuselage, 80 percent of the number of rivets shown in the table may be used. b. For intermediate frames, 60 percent of the number shown may be used. Par 4-58 Page 4-37PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |