PDF Publication Title:

Text from PDF Page: 177

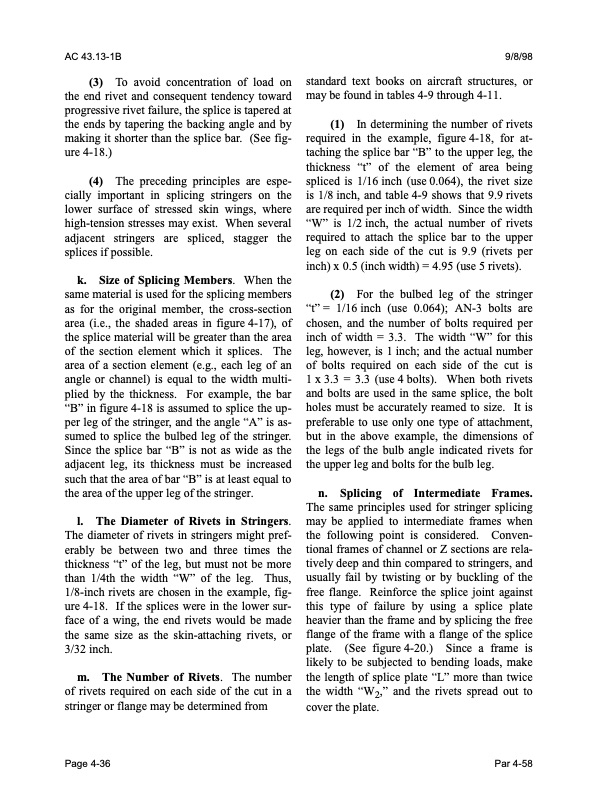

AC 43.13-1B 9/8/98 (3) To avoid concentration of load on the end rivet and consequent tendency toward progressive rivet failure, the splice is tapered at the ends by tapering the backing angle and by making it shorter than the splice bar. (See fig ure 4-18.) (4) The preceding principles are espe cially important in splicing stringers on the lower surface of stressed skin wings, where high-tension stresses may exist. When several adjacent stringers are spliced, stagger the splices if possible. k. Size of Splicing Members. When the same material is used for the splicing members as for the original member, the cross-section area (i.e., the shaded areas in figure 4-17), of the splice material will be greater than the area of the section element which it splices. The area of a section element (e.g., each leg of an angle or channel) is equal to the width multi plied by the thickness. For example, the bar “B” in figure 4-18 is assumed to splice the up per leg of the stringer, and the angle “A” is as sumed to splice the bulbed leg of the stringer. Since the splice bar “B” is not as wide as the adjacent leg, its thickness must be increased such that the area of bar “B” is at least equal to the area of the upper leg of the stringer. l. The Diameter of Rivets in Stringers. The diameter of rivets in stringers might pref erably be between two and three times the thickness “t” of the leg, but must not be more than 1/4th the width “W” of the leg. Thus, 1/8-inch rivets are chosen in the example, fig ure 4-18. If the splices were in the lower sur face of a wing, the end rivets would be made the same size as the skin-attaching rivets, or 3/32 inch. m. The Number of Rivets. The number of rivets required on each side of the cut in a stringer or flange may be determined from standard text books on aircraft structures, or may be found in tables 4-9 through 4-11. (1) In determining the number of rivets required in the example, figure 4-18, for at taching the splice bar “B” to the upper leg, the thickness “t” of the element of area being spliced is 1/16 inch (use 0.064), the rivet size is 1/8 inch, and table 4-9 shows that 9.9 rivets are required per inch of width. Since the width “W” is 1/2 inch, the actual number of rivets required to attach the splice bar to the upper leg on each side of the cut is 9.9 (rivets per inch) x 0.5 (inch width) = 4.95 (use 5 rivets). (2) For the bulbed leg of the stringer “t” = 1/16 inch (use 0.064); AN-3 bolts are chosen, and the number of bolts required per inch of width = 3.3. The width “W” for this leg, however, is 1 inch; and the actual number of bolts required on each side of the cut is 1 x 3.3 = 3.3 (use 4 bolts). When both rivets and bolts are used in the same splice, the bolt holes must be accurately reamed to size. It is preferable to use only one type of attachment, but in the above example, the dimensions of the legs of the bulb angle indicated rivets for the upper leg and bolts for the bulb leg. n. Splicing of Intermediate Frames. The same principles used for stringer splicing may be applied to intermediate frames when the following point is considered. Conven tional frames of channel or Z sections are rela tively deep and thin compared to stringers, and usually fail by twisting or by buckling of the free flange. Reinforce the splice joint against this type of failure by using a splice plate heavier than the frame and by splicing the free flange of the frame with a flange of the splice plate. (See figure 4-20.) Since a frame is likely to be subjected to bending loads, make the length of splice plate “L” more than twice the width “W2,” and the rivets spread out to cover the plate. Page 4-36 Par 4-58PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |