PDF Publication Title:

Text from PDF Page: 132

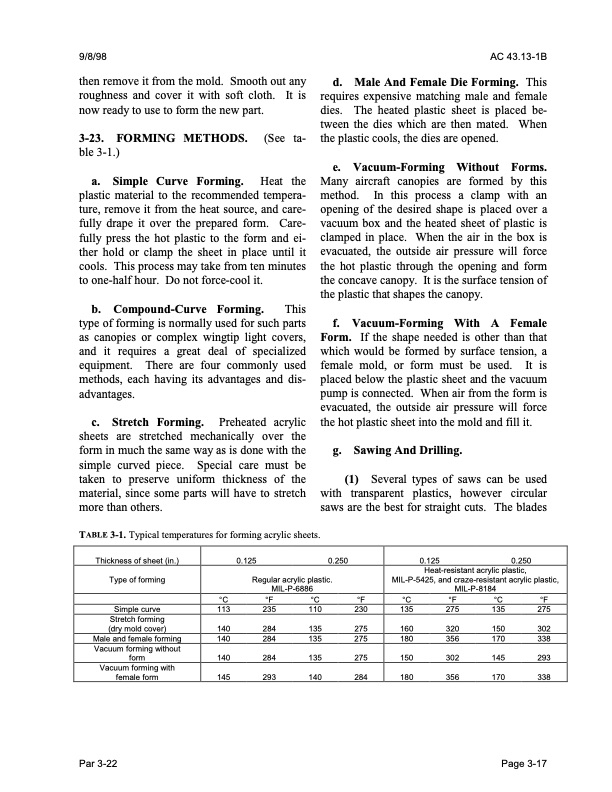

9/8/98 AC 43.13-1B then remove it from the mold. Smooth out any roughness and cover it with soft cloth. It is now ready to use to form the new part. 3-23. FORMING METHODS. (See ta ble 3-1.) a. Simple Curve Forming. Heat the plastic material to the recommended tempera ture, remove it from the heat source, and care fully drape it over the prepared form. Care fully press the hot plastic to the form and ei ther hold or clamp the sheet in place until it cools. This process may take from ten minutes to one-half hour. Do not force-cool it. b. Compound-Curve Forming. This type of forming is normally used for such parts as canopies or complex wingtip light covers, and it requires a great deal of specialized equipment. There are four commonly used methods, each having its advantages and dis advantages. c. Stretch Forming. Preheated acrylic sheets are stretched mechanically over the form in much the same way as is done with the simple curved piece. Special care must be taken to preserve uniform thickness of the material, since some parts will have to stretch more than others. d. Male And Female Die Forming. This requires expensive matching male and female dies. The heated plastic sheet is placed be tween the dies which are then mated. When the plastic cools, the dies are opened. e. Vacuum-Forming Without Forms. Many aircraft canopies are formed by this method. In this process a clamp with an opening of the desired shape is placed over a vacuum box and the heated sheet of plastic is clamped in place. When the air in the box is evacuated, the outside air pressure will force the hot plastic through the opening and form the concave canopy. It is the surface tension of the plastic that shapes the canopy. f. Vacuum-Forming With A Female Form. If the shape needed is other than that which would be formed by surface tension, a female mold, or form must be used. It is placed below the plastic sheet and the vacuum pump is connected. When air from the form is evacuated, the outside air pressure will force the hot plastic sheet into the mold and fill it. g. Sawing And Drilling. (1) Several types of saws can be used with transparent plastics, however circular saws are the best for straight cuts. The blades TABLE 3-1. Typical temperatures for forming acrylic sheets. Thickness of sheet (in.) Type of forming Simple curve Stretch forming (dry mold cover) Male and female forming Vacuum forming without form Vacuum forming with female form 0.125 0.250 Regular acrylic plastic. MIL-P-6886 °C °F °C 0.125 0.250 Heat-resistant acrylic plastic, MIL-P-5425, and craze-resistant acrylic plastic, MIL-P-8184 °F °C °F °C °F 113 235 140 284 140 284 140 284 145 293 110 230 135 275 135 275 150 302 170 338 145 293 170 338 135 275 160 320 135 275 180 356 135 275 150 302 140 284 180 356 Par 3-22 Page 3-17PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |