PDF Publication Title:

Text from PDF Page: 131

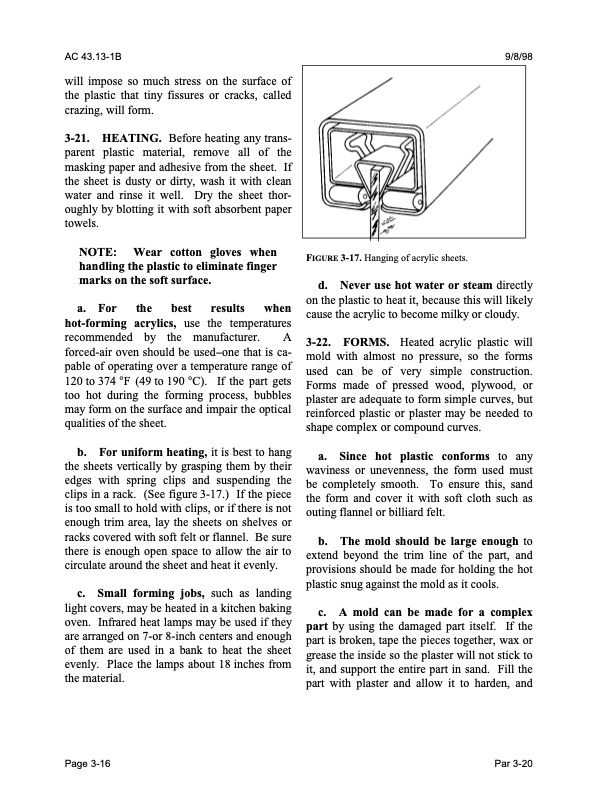

AC 43.13-1B 9/8/98 will impose so much stress on the surface of the plastic that tiny fissures or cracks, called crazing, will form. 3-21. HEATING. Before heating any trans parent plastic material, remove all of the masking paper and adhesive from the sheet. If the sheet is dusty or dirty, wash it with clean water and rinse it well. Dry the sheet thor oughly by blotting it with soft absorbent paper towels. NOTE: Wear cotton gloves when handling the plastic to eliminate finger marks on the soft surface. a. For the best results when hot-forming acrylics, use the temperatures recommended by the manufacturer. A forced-air oven should be used−one that is ca pable of operating over a temperature range of 120 to 374 °F (49 to 190 °C). If the part gets too hot during the forming process, bubbles may form on the surface and impair the optical qualities of the sheet. b. For uniform heating, it is best to hang the sheets vertically by grasping them by their edges with spring clips and suspending the clips in a rack. (See figure 3-17.) If the piece is too small to hold with clips, or if there is not enough trim area, lay the sheets on shelves or racks covered with soft felt or flannel. Be sure there is enough open space to allow the air to circulate around the sheet and heat it evenly. c. Small forming jobs, such as landing light covers, may be heated in a kitchen baking oven. Infrared heat lamps may be used if they are arranged on 7-or 8-inch centers and enough of them are used in a bank to heat the sheet evenly. Place the lamps about 18 inches from the material. FIGURE 3-17. Hanging of acrylic sheets. d. Never use hot water or steam directly on the plastic to heat it, because this will likely cause the acrylic to become milky or cloudy. 3-22. FORMS. Heated acrylic plastic will mold with almost no pressure, so the forms used can be of very simple construction. Forms made of pressed wood, plywood, or plaster are adequate to form simple curves, but reinforced plastic or plaster may be needed to shape complex or compound curves. a. Since hot plastic conforms to any waviness or unevenness, the form used must be completely smooth. To ensure this, sand the form and cover it with soft cloth such as outing flannel or billiard felt. b. The mold should be large enough to extend beyond the trim line of the part, and provisions should be made for holding the hot plastic snug against the mold as it cools. c. A mold can be made for a complex part by using the damaged part itself. If the part is broken, tape the pieces together, wax or grease the inside so the plaster will not stick to it, and support the entire part in sand. Fill the part with plaster and allow it to harden, and Page 3-16 Par 3-20PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |