PDF Publication Title:

Text from PDF Page: 119

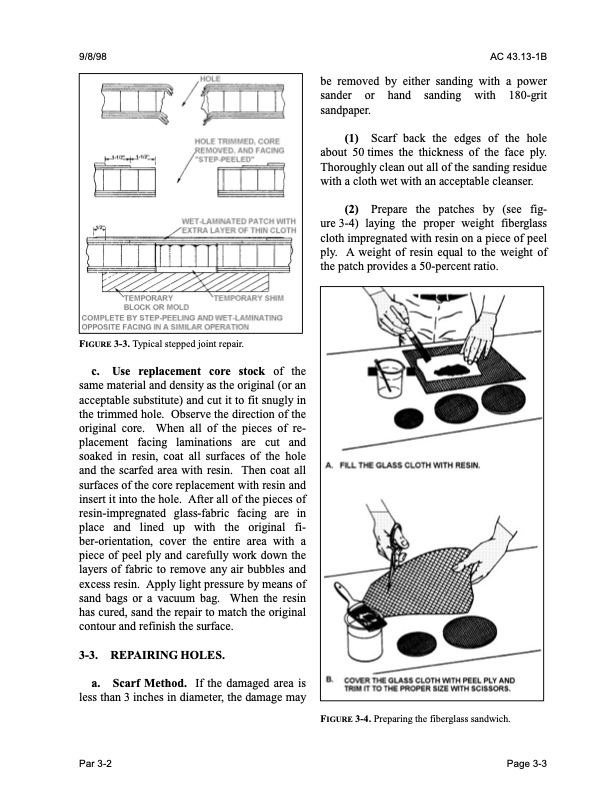

9/8/98 AC 43.13-1B FIGURE 3-3. Typical stepped joint repair. c. Use replacement core stock of the same material and density as the original (or an acceptable substitute) and cut it to fit snugly in the trimmed hole. Observe the direction of the original core. When all of the pieces of re placement facing laminations are cut and soaked in resin, coat all surfaces of the hole and the scarfed area with resin. Then coat all surfaces of the core replacement with resin and insert it into the hole. After all of the pieces of resin-impregnated glass-fabric facing are in place and lined up with the original fi ber-orientation, cover the entire area with a piece of peel ply and carefully work down the layers of fabric to remove any air bubbles and excess resin. Apply light pressure by means of sand bags or a vacuum bag. When the resin has cured, sand the repair to match the original contour and refinish the surface. 3-3. REPAIRING HOLES. a. Scarf Method. If the damaged area is less than 3 inches in diameter, the damage may be removed by either sanding with a power sander or hand sanding with 180-grit sandpaper. (1) Scarf back the edges of the hole about 50 times the thickness of the face ply. Thoroughly clean out all of the sanding residue with a cloth wet with an acceptable cleanser. (2) Prepare the patches by (see fig ure3-4) laying the proper weight fiberglass cloth impregnated with resin on a piece of peel ply. A weight of resin equal to the weight of the patch provides a 50-percent ratio. FIGURE 3-4. Preparing the fiberglass sandwich. Par 3-2 Page 3-3PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |