PDF Publication Title:

Text from PDF Page: 118

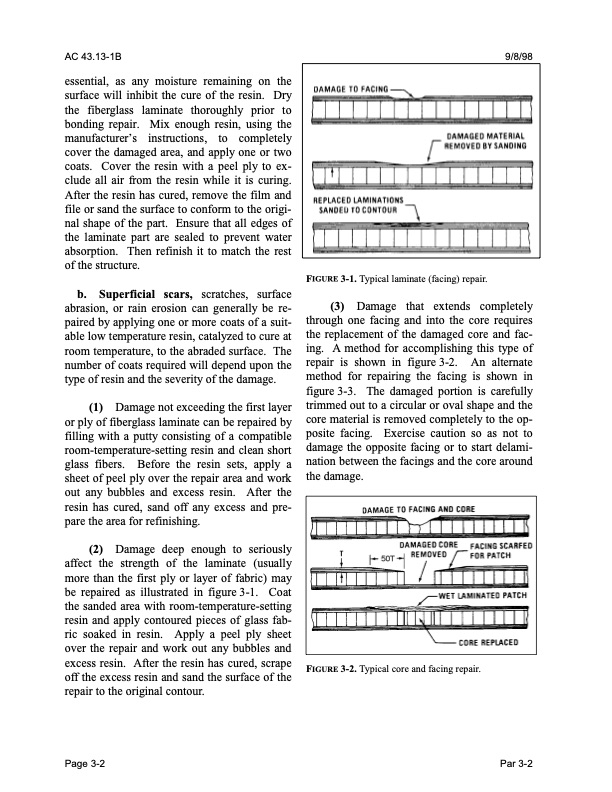

AC 43.13-1B 9/8/98 essential, as any moisture remaining on the surface will inhibit the cure of the resin. Dry the fiberglass laminate thoroughly prior to bonding repair. Mix enough resin, using the manufacturer’s instructions, to completely cover the damaged area, and apply one or two coats. Cover the resin with a peel ply to ex clude all air from the resin while it is curing. After the resin has cured, remove the film and file or sand the surface to conform to the origi nal shape of the part. Ensure that all edges of the laminate part are sealed to prevent water absorption. Then refinish it to match the rest of the structure. b. Superficial scars, scratches, surface abrasion, or rain erosion can generally be re paired by applying one or more coats of a suit able low temperature resin, catalyzed to cure at room temperature, to the abraded surface. The number of coats required will depend upon the type of resin and the severity of the damage. (1) Damage not exceeding the first layer or ply of fiberglass laminate can be repaired by filling with a putty consisting of a compatible room-temperature-setting resin and clean short glass fibers. Before the resin sets, apply a sheet of peel ply over the repair area and work out any bubbles and excess resin. After the resin has cured, sand off any excess and pre pare the area for refinishing. (2) Damage deep enough to seriously affect the strength of the laminate (usually more than the first ply or layer of fabric) may be repaired as illustrated in figure 3-1. Coat the sanded area with room-temperature-setting resin and apply contoured pieces of glass fab ric soaked in resin. Apply a peel ply sheet over the repair and work out any bubbles and excess resin. After the resin has cured, scrape off the excess resin and sand the surface of the repair to the original contour. FIGURE 3-1. Typical laminate (facing) repair. (3) Damage that extends completely through one facing and into the core requires the replacement of the damaged core and fac ing. A method for accomplishing this type of repair is shown in figure 3-2. An alternate method for repairing the facing is shown in figure 3-3. The damaged portion is carefully trimmed out to a circular or oval shape and the core material is removed completely to the op posite facing. Exercise caution so as not to damage the opposite facing or to start delami nation between the facings and the core around the damage. Page 3-2 Par 3-2 FIGURE 3-2. Typical core and facing repair.PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |