PDF Publication Title:

Text from PDF Page: 097

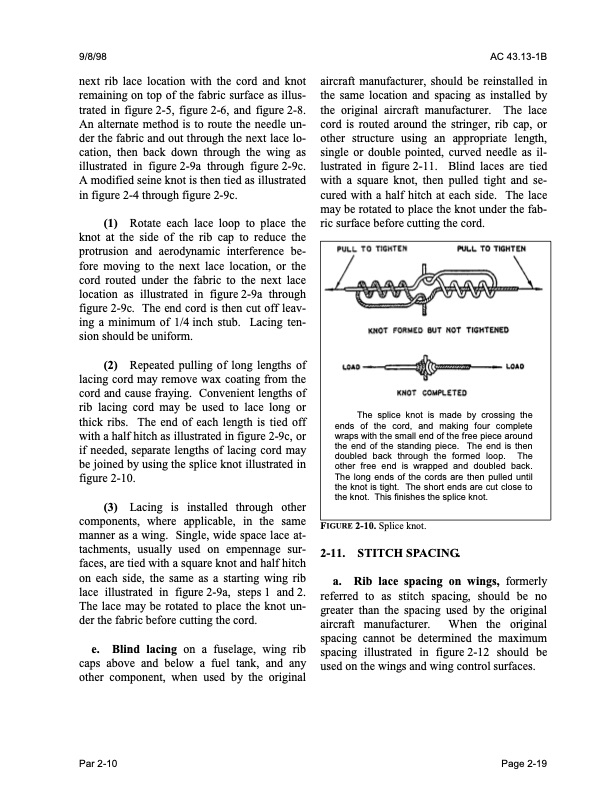

9/8/98 AC 43.13-1B next rib lace location with the cord and knot remaining on top of the fabric surface as illus trated in figure 2-5, figure 2-6, and figure 2-8. An alternate method is to route the needle un der the fabric and out through the next lace lo cation, then back down through the wing as illustrated in figure 2-9a through figure 2-9c. A modified seine knot is then tied as illustrated in figure 2-4 through figure 2-9c. (1) Rotate each lace loop to place the knot at the side of the rib cap to reduce the protrusion and aerodynamic interference be fore moving to the next lace location, or the cord routed under the fabric to the next lace location as illustrated in figure 2-9a through figure 2-9c. The end cord is then cut off leav ing a minimum of 1/4 inch stub. Lacing ten sion should be uniform. (2) Repeated pulling of long lengths of lacing cord may remove wax coating from the cord and cause fraying. Convenient lengths of rib lacing cord may be used to lace long or thick ribs. The end of each length is tied off with a half hitch as illustrated in figure 2-9c, or if needed, separate lengths of lacing cord may be joined by using the splice knot illustrated in figure 2-10. (3) Lacing is installed through other components, where applicable, in the same manner as a wing. Single, wide space lace at tachments, usually used on empennage sur faces, are tied with a square knot and half hitch on each side, the same as a starting wing rib lace illustrated in figure 2-9a, steps 1 and 2. The lace may be rotated to place the knot un der the fabric before cutting the cord. e. Blind lacing on a fuselage, wing rib caps above and below a fuel tank, and any other component, when used by the original aircraft manufacturer, should be reinstalled in the same location and spacing as installed by the original aircraft manufacturer. The lace cord is routed around the stringer, rib cap, or other structure using an appropriate length, single or double pointed, curved needle as il lustrated in figure 2-11. Blind laces are tied with a square knot, then pulled tight and se cured with a half hitch at each side. The lace may be rotated to place the knot under the fab ric surface before cutting the cord. The splice knot is made by crossing the ends of the cord, and making four complete wraps with the small end of the free piece around the end of the standing piece. The end is then doubled back through the formed loop. The other free end is wrapped and doubled back. The long ends of the cords are then pulled until the knot is tight. The short ends are cut close to the knot. This finishes the splice knot. Par 2-10 Page 2-19 FIGURE 2-10. Splice knot. 2-11. STITCH SPACING. a. Rib lace spacing on wings, formerly referred to as stitch spacing, should be no greater than the spacing used by the original aircraft manufacturer. When the original spacing cannot be determined the maximum spacing illustrated in figure2-12 should be used on the wings and wing control surfaces.PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |