PDF Publication Title:

Text from PDF Page: 060

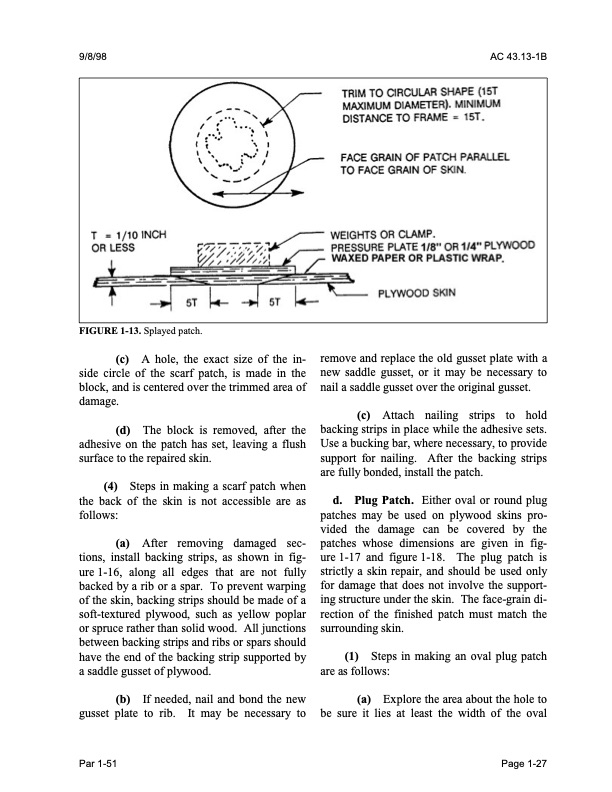

9/8/98 AC 43.13-1B FIGURE 1-13. Splayed patch. (c) A hole, the exact size of the in- side circle of the scarf patch, is made in the block, and is centered over the trimmed area of damage. (d) The block is removed, after the adhesive on the patch has set, leaving a flush surface to the repaired skin. (4) Steps in making a scarf patch when the back of the skin is not accessible are as follows: (a) After removing damaged sec- tions, install backing strips, as shown in fig- ure 1-16, along all edges that are not fully backed by a rib or a spar. To prevent warping of the skin, backing strips should be made of a soft-textured plywood, such as yellow poplar or spruce rather than solid wood. All junctions between backing strips and ribs or spars should have the end of the backing strip supported by a saddle gusset of plywood. (b) If needed, nail and bond the new gusset plate to rib. It may be necessary to remove and replace the old gusset plate with a new saddle gusset, or it may be necessary to nail a saddle gusset over the original gusset. (c) Attach nailing strips to hold backing strips in place while the adhesive sets. Use a bucking bar, where necessary, to provide support for nailing. After the backing strips are fully bonded, install the patch. d. Plug Patch. Either oval or round plug patches may be used on plywood skins pro- vided the damage can be covered by the patches whose dimensions are given in fig- ure 1-17 and figure 1-18. The plug patch is strictly a skin repair, and should be used only for damage that does not involve the support- ing structure under the skin. The face-grain di- rection of the finished patch must match the surrounding skin. (1) Steps in making an oval plug patch are as follows: (a) Explore the area about the hole to be sure it lies at least the width of the oval Par 1-51 Page 1-27PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |