PDF Publication Title:

Text from PDF Page: 059

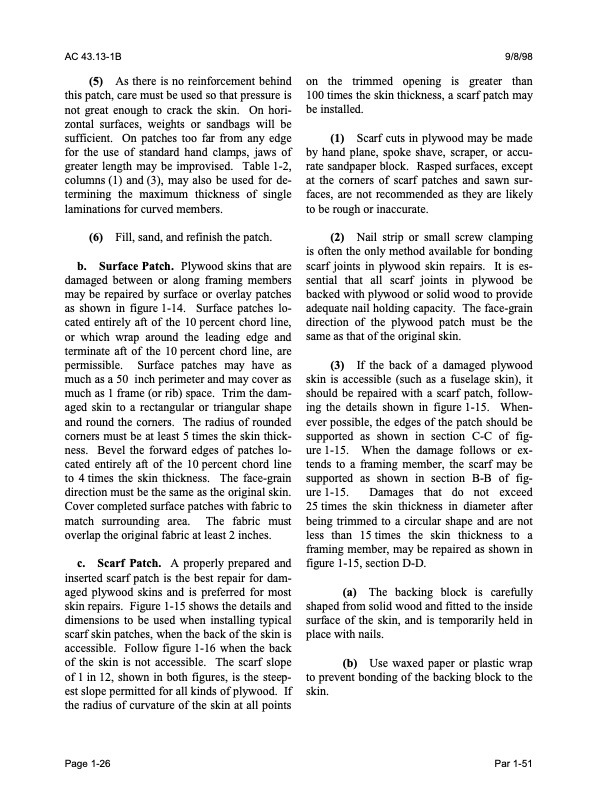

AC 43.13-1B 9/8/98 (5) As there is no reinforcement behind this patch, care must be used so that pressure is not great enough to crack the skin. On hori- zontal surfaces, weights or sandbags will be sufficient. On patches too far from any edge for the use of standard hand clamps, jaws of greater length may be improvised. Table 1-2, columns (1) and (3), may also be used for de- termining the maximum thickness of single laminations for curved members. (6) Fill, sand, and refinish the patch. b. Surface Patch. Plywood skins that are damaged between or along framing members may be repaired by surface or overlay patches as shown in figure 1-14. Surface patches lo- cated entirely aft of the 10 percent chord line, or which wrap around the leading edge and terminate aft of the 10 percent chord line, are permissible. Surface patches may have as much as a 50 inch perimeter and may cover as much as 1 frame (or rib) space. Trim the dam- aged skin to a rectangular or triangular shape and round the corners. The radius of rounded corners must be at least 5 times the skin thick- ness. Bevel the forward edges of patches lo- cated entirely aft of the 10 percent chord line to 4 times the skin thickness. The face-grain direction must be the same as the original skin. Cover completed surface patches with fabric to match surrounding area. The fabric must overlap the original fabric at least 2 inches. c. Scarf Patch. A properly prepared and inserted scarf patch is the best repair for dam- aged plywood skins and is preferred for most skin repairs. Figure 1-15 shows the details and dimensions to be used when installing typical scarf skin patches, when the back of the skin is accessible. Follow figure 1-16 when the back of the skin is not accessible. The scarf slope of 1 in 12, shown in both figures, is the steep- est slope permitted for all kinds of plywood. If the radius of curvature of the skin at all points on the trimmed opening is greater than 100 times the skin thickness, a scarf patch may be installed. (1) Scarf cuts in plywood may be made by hand plane, spoke shave, scraper, or accu- rate sandpaper block. Rasped surfaces, except at the corners of scarf patches and sawn sur- faces, are not recommended as they are likely to be rough or inaccurate. (2) Nail strip or small screw clamping is often the only method available for bonding scarf joints in plywood skin repairs. It is es- sential that all scarf joints in plywood be backed with plywood or solid wood to provide adequate nail holding capacity. The face-grain direction of the plywood patch must be the same as that of the original skin. (3) If the back of a damaged plywood skin is accessible (such as a fuselage skin), it should be repaired with a scarf patch, follow- ing the details shown in figure 1-15. When- ever possible, the edges of the patch should be supported as shown in section C-C of fig- ure 1-15. When the damage follows or ex- tends to a framing member, the scarf may be supported as shown in section B-B of fig- ure 1-15. Damages that do not exceed 25 times the skin thickness in diameter after being trimmed to a circular shape and are not less than 15times the skin thickness to a framing member, may be repaired as shown in figure 1-15, section D-D. (a) The backing block is carefully shaped from solid wood and fitted to the inside surface of the skin, and is temporarily held in place with nails. (b) Use waxed paper or plastic wrap to prevent bonding of the backing block to the skin. Page 1-26 Par 1-51PDF Image | AFS-640

PDF Search Title:

AFS-640Original File Name Searched:

ac_43.13-1b_w-chg1.pdfDIY PDF Search: Google It | Yahoo | Bing

5,000 BF Shipping Container Lumber Dry Kiln For Quality Lumber The 5,000 BF container kiln consists of one 40 foot high-cube aluminum shipping container... More Info

Shipping Container Lumber Dry Kilns by Global Energy Global Energy designed and developed the container kiln back in 1991. The purpose is to give access to portable sawmill owners, furniture makers, and small business the value added profit of dry kiln lumber and quality hardwoods... More Info

Vacuum Kiln Conversion Kit for Lumber and Wood Dry Kilns Convert your existing conventional dry kiln into a fast drying vacuum kiln. Similar to vacuum bagging in the boat building and aircraft industry, we have come up with a proprietary process which allows you to build a very simple vacuum kiln at a fraction of the price, and without the intensive conventional metal chamber structure... More Info

Vacuum Pump Cart System for Bagging Clamping Wood Drying and more Vacuum Cart with 2HP Pump and Dual Pistons with multiple multiplex vacuum ports and liquid reservoir... More Info

Vacuum Bagging Basics Vacuum bagging is a method of clamping, which has traditionally been used in the composites industry, but can also be used for vacuum drying materials, including wood products... More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |