PDF Publication Title:

Text from PDF Page: 051

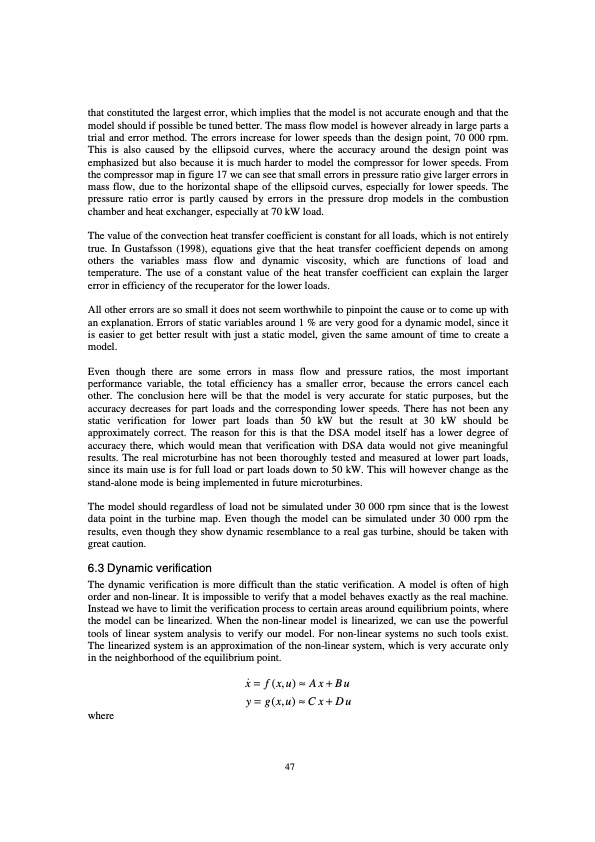

that constituted the largest error, which implies that the model is not accurate enough and that the model should if possible be tuned better. The mass flow model is however already in large parts a trial and error method. The errors increase for lower speeds than the design point, 70 000 rpm. This is also caused by the ellipsoid curves, where the accuracy around the design point was emphasized but also because it is much harder to model the compressor for lower speeds. From the compressor map in figure 17 we can see that small errors in pressure ratio give larger errors in mass flow, due to the horizontal shape of the ellipsoid curves, especially for lower speeds. The pressure ratio error is partly caused by errors in the pressure drop models in the combustion chamber and heat exchanger, especially at 70 kW load. The value of the convection heat transfer coefficient is constant for all loads, which is not entirely true. In Gustafsson (1998), equations give that the heat transfer coefficient depends on among others the variables mass flow and dynamic viscosity, which are functions of load and temperature. The use of a constant value of the heat transfer coefficient can explain the larger error in efficiency of the recuperator for the lower loads. All other errors are so small it does not seem worthwhile to pinpoint the cause or to come up with an explanation. Errors of static variables around 1 % are very good for a dynamic model, since it is easier to get better result with just a static model, given the same amount of time to create a model. Even though there are some errors in mass flow and pressure ratios, the most important performance variable, the total efficiency has a smaller error, because the errors cancel each other. The conclusion here will be that the model is very accurate for static purposes, but the accuracy decreases for part loads and the corresponding lower speeds. There has not been any static verification for lower part loads than 50 kW but the result at 30 kW should be approximately correct. The reason for this is that the DSA model itself has a lower degree of accuracy there, which would mean that verification with DSA data would not give meaningful results. The real microturbine has not been thoroughly tested and measured at lower part loads, since its main use is for full load or part loads down to 50 kW. This will however change as the stand-alone mode is being implemented in future microturbines. The model should regardless of load not be simulated under 30 000 rpm since that is the lowest data point in the turbine map. Even though the model can be simulated under 30 000 rpm the results, even though they show dynamic resemblance to a real gas turbine, should be taken with great caution. 6.3 Dynamic verification The dynamic verification is more difficult than the static verification. A model is often of high order and non-linear. It is impossible to verify that a model behaves exactly as the real machine. Instead we have to limit the verification process to certain areas around equilibrium points, where the model can be linearized. When the non-linear model is linearized, we can use the powerful tools of linear system analysis to verify our model. For non-linear systems no such tools exist. The linearized system is an approximation of the non-linear system, which is very accurate only in the neighborhood of the equilibrium point. where x& = f ( x , u ) ≈ A x + B u y = g(x,u) ≈ C x + Du 47PDF Image | Modelling of Microturbine Systems

PDF Search Title:

Modelling of Microturbine SystemsOriginal File Name Searched:

Model_turbiny_T100.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |