PDF Publication Title:

Text from PDF Page: 003

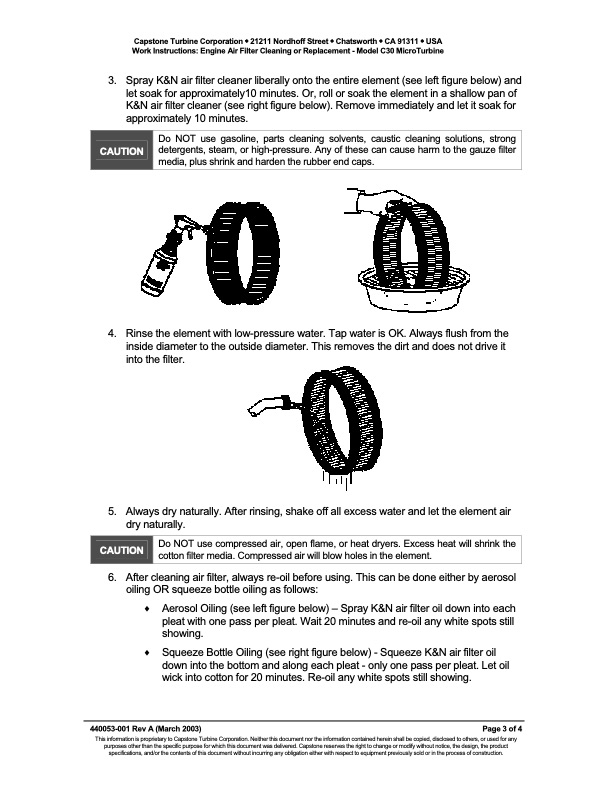

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Work Instructions: Engine Air Filter Cleaning or Replacement - Model C30 MicroTurbine 3. Spray K&N air filter cleaner liberally onto the entire element (see left figure below) and let soak for approximately10 minutes. Or, roll or soak the element in a shallow pan of K&N air filter cleaner (see right figure below). Remove immediately and let it soak for approximately 10 minutes. Do NOT use gasoline, parts cleaning solvents, caustic cleaning solutions, strong CAUTION detergents, steam, or high-pressure. Any of these can cause harm to the gauze filter media, plus shrink and harden the rubber end caps. 4. Rinse the element with low-pressure water. Tap water is OK. Always flush from the inside diameter to the outside diameter. This removes the dirt and does not drive it into the filter. 5. Always dry naturally. After rinsing, shake off all excess water and let the element air dry naturally. CAUTION Do NOT use compressed air, open flame, or heat dryers. Excess heat will shrink the cotton filter media. Compressed air will blow holes in the element. 6. After cleaning air filter, always re-oil before using. This can be done either by aerosol oiling OR squeeze bottle oiling as follows: ♦ Aerosol Oiling (see left figure below) – Spray K&N air filter oil down into each pleat with one pass per pleat. Wait 20 minutes and re-oil any white spots still showing. ♦ Squeeze Bottle Oiling (see right figure below) - Squeeze K&N air filter oil down into the bottom and along each pleat - only one pass per pleat. Let oil wick into cotton for 20 minutes. Re-oil any white spots still showing. 440053-001 Rev A (March 2003) Page 3 of 4 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Work Instructions Engine Air Filter Cleaning or Replacement Capstone Model C30 MicroTurbine

PDF Search Title:

Work Instructions Engine Air Filter Cleaning or Replacement Capstone Model C30 MicroTurbineOriginal File Name Searched:

440053 C30 Air Filter Cleaning Mar03.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |