PDF Publication Title:

Text from PDF Page: 014

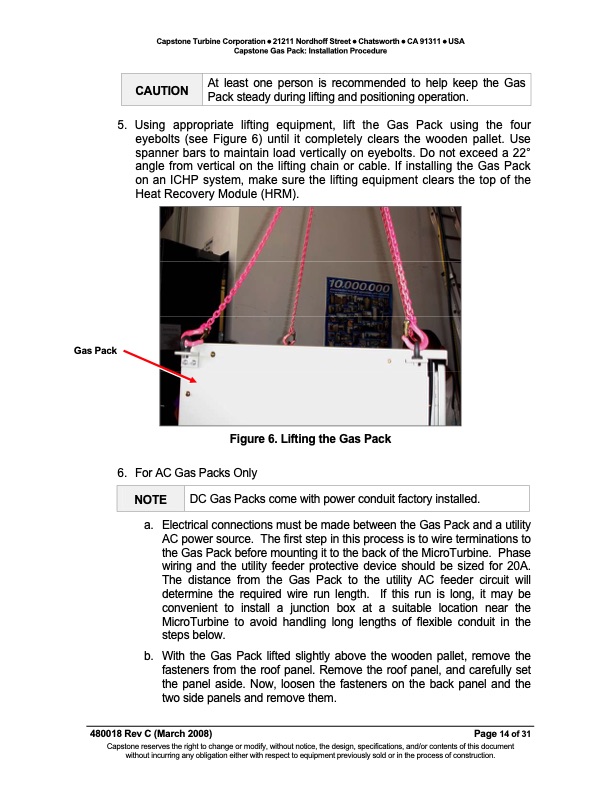

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Capstone Gas Pack: Installation Procedure CAUTION At least one person is recommended to help keep the Gas Pack steady during lifting and positioning operation. Gas Pack 5. Using appropriate lifting equipment, lift the Gas Pack using the four eyebolts (see Figure 6) until it completely clears the wooden pallet. Use spanner bars to maintain load vertically on eyebolts. Do not exceed a 22° angle from vertical on the lifting chain or cable. If installing the Gas Pack on an ICHP system, make sure the lifting equipment clears the top of the Heat Recovery Module (HRM). Figure 6. Lifting the Gas Pack 6. ForACGasPacksOnly NOTE DC Gas Packs come with power conduit factory installed. a. ElectricalconnectionsmustbemadebetweentheGasPackandautility AC power source. The first step in this process is to wire terminations to the Gas Pack before mounting it to the back of the MicroTurbine. Phase wiring and the utility feeder protective device should be sized for 20A. The distance from the Gas Pack to the utility AC feeder circuit will determine the required wire run length. If this run is long, it may be convenient to install a junction box at a suitable location near the MicroTurbine to avoid handling long lengths of flexible conduit in the steps below. b. With the Gas Pack lifted slightly above the wooden pallet, remove the fasteners from the roof panel. Remove the roof panel, and carefully set the panel aside. Now, loosen the fasteners on the back panel and the two side panels and remove them. 480018 Rev C (March 2008) Page 14 of 31 Capstone reserves the right to change or modify, without notice, the design, specifications, and/or contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | CAPSTONE GAS PACK INSTALLATION PROCEDURE

PDF Search Title:

CAPSTONE GAS PACK INSTALLATION PROCEDUREOriginal File Name Searched:

480018C_AG_GASPACK_INSTALL_PROC.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |