PDF Publication Title:

Text from PDF Page: 004

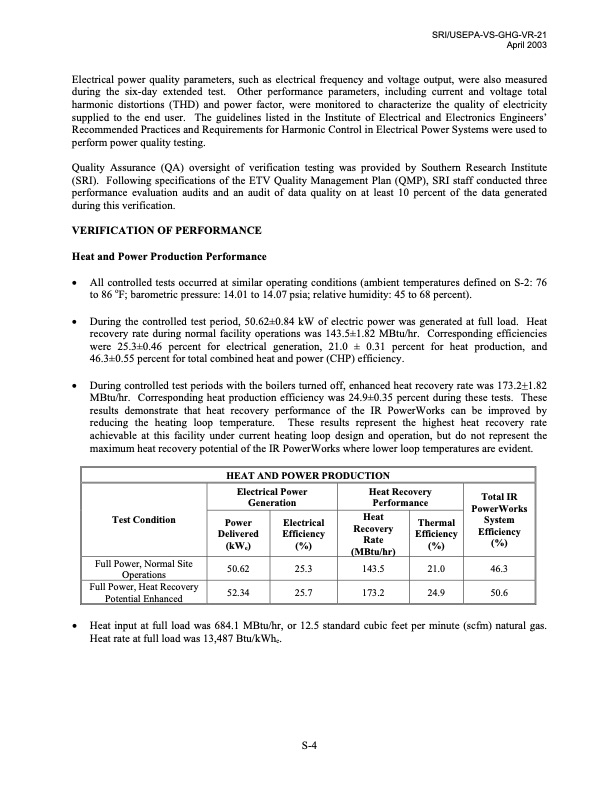

SRI/USEPA-VS-GHG-VR-21 April 2003 Electrical power quality parameters, such as electrical frequency and voltage output, were also measured during the six-day extended test. Other performance parameters, including current and voltage total harmonic distortions (THD) and power factor, were monitored to characterize the quality of electricity supplied to the end user. The guidelines listed in the Institute of Electrical and Electronics Engineers’ Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems were used to perform power quality testing. Quality Assurance (QA) oversight of verification testing was provided by Southern Research Institute (SRI). Following specifications of the ETV Quality Management Plan (QMP), SRI staff conducted three performance evaluation audits and an audit of data quality on at least 10 percent of the data generated during this verification. VERIFICATION OF PERFORMANCE Heat and Power Production Performance • All controlled tests occurred at similar operating conditions (ambient temperatures defined on S-2: 76 to 86 oF; barometric pressure: 14.01 to 14.07 psia; relative humidity: 45 to 68 percent). • During the controlled test period, 50.62±0.84 kW of electric power was generated at full load. Heat recovery rate during normal facility operations was 143.5±1.82 MBtu/hr. Corresponding efficiencies were 25.3±0.46 percent for electrical generation, 21.0 ± 0.31 percent for heat production, and 46.3±0.55 percent for total combined heat and power (CHP) efficiency. • During controlled test periods with the boilers turned off, enhanced heat recovery rate was 173.2+1.82 MBtu/hr. Corresponding heat production efficiency was 24.9±0.35 percent during these tests. These results demonstrate that heat recovery performance of the IR PowerWorks can be improved by reducing the heating loop temperature. These results represent the highest heat recovery rate achievable at this facility under current heating loop design and operation, but do not represent the maximum heat recovery potential of the IR PowerWorks where lower loop temperatures are evident. HEAT AND POWER PRODUCTION Electrical Power Generation 50.62 25.3 52.34 25.7 Heat Recovery Performance Total IR PowerWorks System Efficiency (%) Power Delivered (kWe) Electrical Efficiency (%) Heat Recovery Rate (MBtu/hr) Thermal Efficiency (%) Test Condition Full Power, Normal Site Operations Full Power, Heat Recovery Potential Enhanced 143.5 173.2 21.0 46.3 24.9 50.6 • Heat input at full load was 684.1 MBtu/hr, or 12.5 standard cubic feet per minute (scfm) natural gas. Heat rate at full load was 13,487 Btu/kWhe. S-4PDF Image | THE ENVIRONMENTAL TECHNOLOGY VERIFICATION PROGRAM

PDF Search Title:

THE ENVIRONMENTAL TECHNOLOGY VERIFICATION PROGRAMOriginal File Name Searched:

Ingersoll-Rand-ETV-Statement.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |