PDF Publication Title:

Text from PDF Page: 003

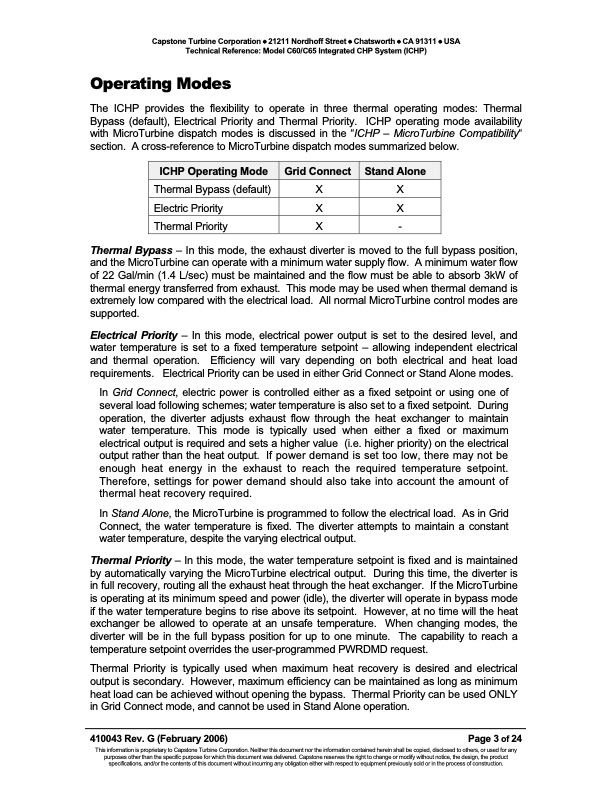

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Model C60/C65 Integrated CHP System (ICHP) Operating Modes The ICHP provides the flexibility to operate in three thermal operating modes: Thermal Bypass (default), Electrical Priority and Thermal Priority. ICHP operating mode availability with MicroTurbine dispatch modes is discussed in the “ICHP – MicroTurbine Compatibility“ section. A cross-reference to MicroTurbine dispatch modes summarized below. ICHP Operating Mode Grid Connect Stand Alone Thermal Bypass (default) Electric Priority Thermal Priority X X X X X - Thermal Bypass – In this mode, the exhaust diverter is moved to the full bypass position, and the MicroTurbine can operate with a minimum water supply flow. A minimum water flow of 22 Gal/min (1.4 L/sec) must be maintained and the flow must be able to absorb 3kW of thermal energy transferred from exhaust. This mode may be used when thermal demand is extremely low compared with the electrical load. All normal MicroTurbine control modes are supported. Electrical Priority – In this mode, electrical power output is set to the desired level, and water temperature is set to a fixed temperature setpoint – allowing independent electrical and thermal operation. Efficiency will vary depending on both electrical and heat load requirements. Electrical Priority can be used in either Grid Connect or Stand Alone modes. In Grid Connect, electric power is controlled either as a fixed setpoint or using one of several load following schemes; water temperature is also set to a fixed setpoint. During operation, the diverter adjusts exhaust flow through the heat exchanger to maintain water temperature. This mode is typically used when either a fixed or maximum electrical output is required and sets a higher value (i.e. higher priority) on the electrical output rather than the heat output. If power demand is set too low, there may not be enough heat energy in the exhaust to reach the required temperature setpoint. Therefore, settings for power demand should also take into account the amount of thermal heat recovery required. In Stand Alone, the MicroTurbine is programmed to follow the electrical load. As in Grid Connect, the water temperature is fixed. The diverter attempts to maintain a constant water temperature, despite the varying electrical output. Thermal Priority – In this mode, the water temperature setpoint is fixed and is maintained by automatically varying the MicroTurbine electrical output. During this time, the diverter is in full recovery, routing all the exhaust heat through the heat exchanger. If the MicroTurbine is operating at its minimum speed and power (idle), the diverter will operate in bypass mode if the water temperature begins to rise above its setpoint. However, at no time will the heat exchanger be allowed to operate at an unsafe temperature. When changing modes, the diverter will be in the full bypass position for up to one minute. The capability to reach a temperature setpoint overrides the user-programmed PWRDMD request. Thermal Priority is typically used when maximum heat recovery is desired and electrical output is secondary. However, maximum efficiency can be maintained as long as minimum heat load can be achieved without opening the bypass. Thermal Priority can be used ONLY in Grid Connect mode, and cannot be used in Stand Alone operation. 410043 Rev. G (February 2006) Page 3 of 24 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Technical Reference Model C60/C65Integrated CHP System (ICHP)

PDF Search Title:

Technical Reference Model C60/C65Integrated CHP System (ICHP)Original File Name Searched:

410043_ICHP_Tech_Ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |