PDF Publication Title:

Text from PDF Page: 002

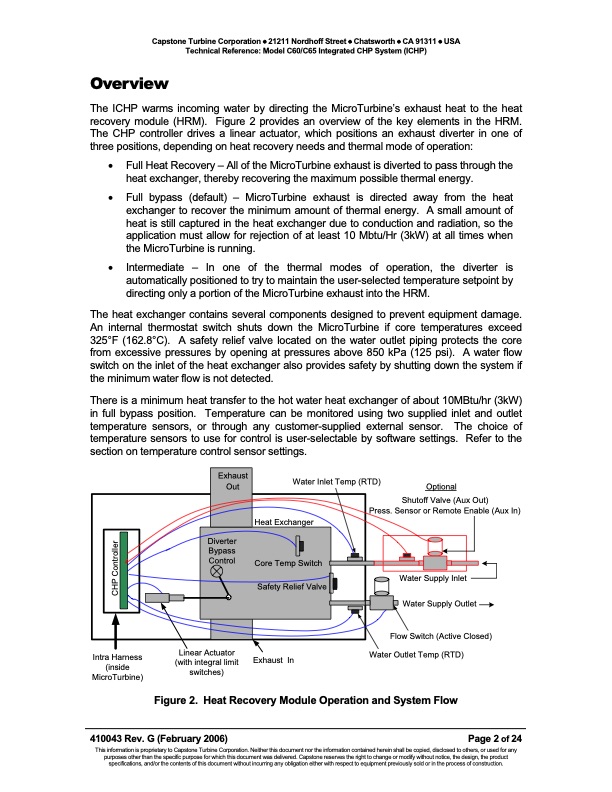

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Technical Reference: Model C60/C65 Integrated CHP System (ICHP) Overview The ICHP warms incoming water by directing the MicroTurbine’s exhaust heat to the heat recovery module (HRM). Figure 2 provides an overview of the key elements in the HRM. The CHP controller drives a linear actuator, which positions an exhaust diverter in one of three positions, depending on heat recovery needs and thermal mode of operation: • Full Heat Recovery – All of the MicroTurbine exhaust is diverted to pass through the heat exchanger, thereby recovering the maximum possible thermal energy. • Full bypass (default) – MicroTurbine exhaust is directed away from the heat exchanger to recover the minimum amount of thermal energy. A small amount of heat is still captured in the heat exchanger due to conduction and radiation, so the application must allow for rejection of at least 10 Mbtu/Hr (3kW) at all times when the MicroTurbine is running. • Intermediate – In one of the thermal modes of operation, the diverter is automatically positioned to try to maintain the user-selected temperature setpoint by directing only a portion of the MicroTurbine exhaust into the HRM. The heat exchanger contains several components designed to prevent equipment damage. An internal thermostat switch shuts down the MicroTurbine if core temperatures exceed 325°F (162.8°C). A safety relief valve located on the water outlet piping protects the core from excessive pressures by opening at pressures above 850 kPa (125 psi). A water flow switch on the inlet of the heat exchanger also provides safety by shutting down the system if the minimum water flow is not detected. There is a minimum heat transfer to the hot water heat exchanger of about 10MBtu/hr (3kW) in full bypass position. Temperature can be monitored using two supplied inlet and outlet temperature sensors, or through any customer-supplied external sensor. The choice of temperature sensors to use for control is user-selectable by software settings. Refer to the section on temperature control sensor settings. Water Inlet Temp (RTD) Optional Exhaust Out Heat Exchanger Diverter Bypass Control Core Temp Switch Safety Relief Valve Shutoff Valve (Aux Out) Press. Sensor or Remote Enable (Aux In) Water Supply Inlet Water Supply Outlet Flow Switch (Active Closed) Intra Harness (inside MicroTurbine) Linear Actuator (with integral limit switches) Exhaust In Water Outlet Temp (RTD) Figure 2. Heat Recovery Module Operation and System Flow 410043 Rev. G (February 2006) Page 2 of 24 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction. CHP ControllerPDF Image | Technical Reference Model C60/C65Integrated CHP System (ICHP)

PDF Search Title:

Technical Reference Model C60/C65Integrated CHP System (ICHP)Original File Name Searched:

410043_ICHP_Tech_Ref.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |