PDF Publication Title:

Text from PDF Page: 002

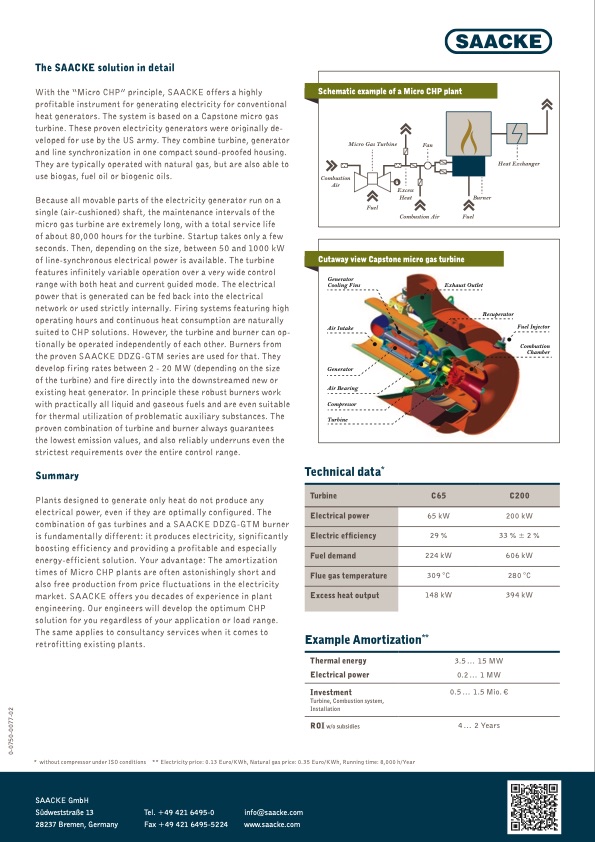

The SAACKE solution in detail With the “Micro CHP” principle, SAACKE offers a highly profitable instrument for generating electricity for conventional heat generators. The system is based on a Capstone micro gas turbine. These proven electricity generators were originally de- veloped for use by the US army. They combine turbine, generator and line synchronization in one compact sound-proofed housing. They are typically operated with natural gas, but are also able to use biogas, fuel oil or biogenic oils. Because all movable parts of the electricity generator run on a single (air-cushioned) shaft, the maintenance intervals of the micro gas turbine are extremely long, with a total service life of about 80,000 hours for the turbine. Startup takes only a few seconds. Then, depending on the size, between 50 and 1000 kW of line-synchronous electrical power is available. The turbine features infinitely variable operation over a very wide control range with both heat and current guided mode. The electrical power that is generated can be fed back into the electrical network or used strictly internally. Firing systems featuring high operating hours and continuous heat consumption are naturally suited to CHP solutions. However, the turbine and burner can op- tionally be operated independently of each other. Burners from the proven SAACKE DDZG-GTM series are used for that. They develop firing rates between 2 - 20 MW (depending on the size of the turbine) and fire directly into the downstreamed new or existing heat generator. In principle these robust burners work with practically all liquid and gaseous fuels and are even suitable for thermal utilization of problematic auxiliary substances. The proven combination of turbine and burner always guarantees the lowest emission values, and also reliably underruns even the strictest requirements over the entire control range. Summary Plants designed to generate only heat do not produce any electrical power, even if they are optimally configured. The combination of gas turbines and a SAACKE DDZG-GTM burner is fundamentally different: it produces electricity, significantly boosting efficiency and providing a profitable and especially energy-efficient solution. Your advantage: The amortization times of Micro CHP plants are often astonishingly short and also free production from price fluctuations in the electricity market. SAACKE offers you decades of experience in plant engineering. Our engineers will develop the optimum CHP solution for you regardless of your application or load range. The same applies to consultancy services when it comes to retrofitting existing plants. Technical data* Schematic example of a Micro CHP plant Combustion Air G Fuel Excess Heat Cutaway view Capstone micro gas turbine Generator Cooling Fins Air Intake Generator Air Bearing Compressor Turbine Exhaust Outlet Recuperator Fuel Injector Combustion Chamber Turbine C65 Electrical power C200 Electric efficiency Fuel demand Flue gas temperature Excess heat output Example Amortization** 200 kW 33 % ± 2 % 606 kW 280 °C 394 kW 0.5 ... 1.5 Mio. € 4 ... 2 Years 65 kW 29 % 224 kW 309 °C 148 kW Thermal energy Electrical power Investment Turbine, Combustion system, Installation ROI w/o subsidies * without compressor under ISO conditions ** Electricity price: 0.13 Euro/KWh, Natural gas price: 0.35 Euro/KWh, Running time: 8,000 h/Year Micro Gas Turbine Fan Burner Combustion Air Fuel 3.5 ... 15 MW 0.2 ... 1 MW Heat Exchanger SAACKE GmbH Südweststraße 13 Tel. +49 421 6495-0 info@saacke.com 28237 Bremen, Germany Fax +49 421 6495-5224 www.saacke.com 0-0750-0077-02PDF Image | Power production through CHP combined heat and power

PDF Search Title:

Power production through CHP combined heat and powerOriginal File Name Searched:

0-0750-0077-02-WEB.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |