PDF Publication Title:

Text from PDF Page: 006

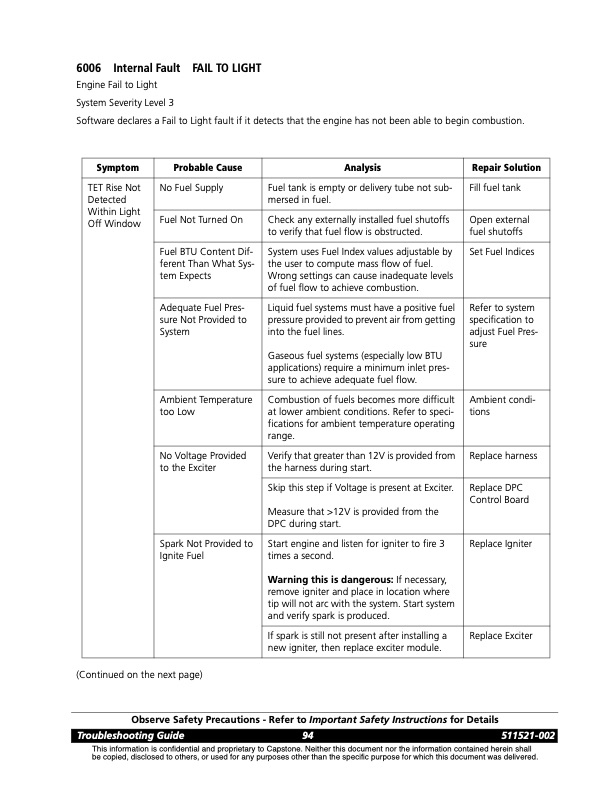

6006 Internal Fault FAIL TO LIGHT Engine Fail to Light System Severity Level 3 Software declares a Fail to Light fault if it detects that the engine has not been able to begin combustion. Symptom Probable Cause Analysis Repair Solution TET Rise Not Detected Within Light Off Window No Fuel Supply Fuel tank is empty or delivery tube not sub- mersed in fuel. Fill fuel tank Fuel Not Turned On Check any externally installed fuel shutoffs to verify that fuel flow is obstructed. Open external fuel shutoffs Fuel BTU Content Dif- ferent Than What Sys- tem Expects System uses Fuel Index values adjustable by the user to compute mass flow of fuel. Wrong settings can cause inadequate levels of fuel flow to achieve combustion. Set Fuel Indices Adequate Fuel Pres- sure Not Provided to System Liquid fuel systems must have a positive fuel pressure provided to prevent air from getting into the fuel lines. Gaseous fuel systems (especially low BTU applications) require a minimum inlet pres- sure to achieve adequate fuel flow. Refer to system specification to adjust Fuel Pres- sure Ambient Temperature too Low Combustion of fuels becomes more difficult at lower ambient conditions. Refer to speci- fications for ambient temperature operating range. Ambient condi- tions No Voltage Provided to the Exciter Verify that greater than 12V is provided from the harness during start. Replace harness Skip this step if Voltage is present at Exciter. Measure that >12V is provided from the DPC during start. Replace DPC Control Board Spark Not Provided to Ignite Fuel Start engine and listen for igniter to fire 3 times a second. Warning this is dangerous: If necessary, remove igniter and place in location where tip will not arc with the system. Start system and verify spark is produced. Replace Igniter If spark is still not present after installing a new igniter, then replace exciter module. Replace Exciter (Continued on the next page) Observe Safety Precautions - Refer to Important Safety Instructions for Details Troubleshooting Guide 94 511521-002 This information is confidential and proprietary to Capstone. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered.PDF Image | SERIES 6000 FAULT CODES Operational Faults

PDF Search Title:

SERIES 6000 FAULT CODES Operational FaultsOriginal File Name Searched:

06_6000Faults.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |