PDF Publication Title:

Text from PDF Page: 030

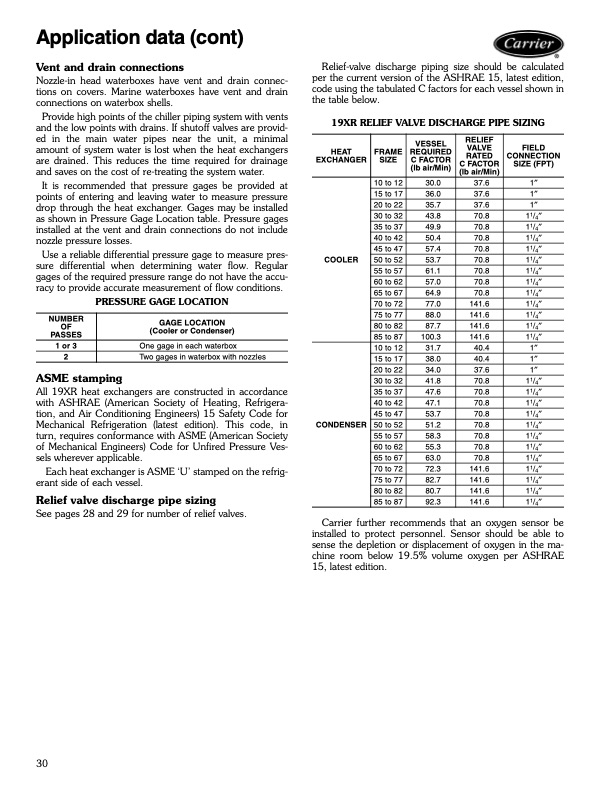

Application data (cont) Vent and drain connections Nozzle-in head waterboxes have vent and drain connec- tions on covers. Marine waterboxes have vent and drain connections on waterbox shells. Provide high points of the chiller piping system with vents and the low points with drains. If shutoff valves are provid- ed in the main water pipes near the unit, a minimal amount of system water is lost when the heat exchangers are drained. This reduces the time required for drainage and saves on the cost of re-treating the system water. It is recommended that pressure gages be provided at points of entering and leaving water to measure pressure drop through the heat exchanger. Gages may be installed as shown in Pressure Gage Location table. Pressure gages installed at the vent and drain connections do not include nozzle pressure losses. Use a reliable differential pressure gage to measure pres- sure differential when determining water flow. Regular gages of the required pressure range do not have the accu- racy to provide accurate measurement of flow conditions. Relief-valve discharge piping size should be calculated per the current version of the ASHRAE 15, latest edition, code using the tabulated C factors for each vessel shown in the table below. 19XR RELIEF VALVE DISCHARGE PIPE SIZING FRAME SIZE VESSEL REQUIRED C FACTOR (lb air/Min) RELIEF VALVE RATED C FACTOR (lb air/Min) 10 to 12 30.0 37.6 15 to 17 36.0 37.6 20 to 22 35.7 37.6 30 to 32 43.8 70.8 35 to 37 49.9 70.8 40 to 42 50.4 70.8 45 to 47 57.4 70.8 50 to 52 53.7 70.8 55 to 57 61.1 70.8 60 to 62 57.0 70.8 65 to 67 64.9 70.8 70 to 72 77.0 141.6 75 to 77 88.0 141.6 80 to 82 87.7 141.6 85 to 87 100.3 141.6 10 to 12 31.7 40.4 15 to 17 38.0 40.4 20 to 22 34.0 37.6 30 to 32 41.8 70.8 35 to 37 47.6 70.8 40 to 42 47.1 70.8 45 to 47 53.7 70.8 50 to 52 51.2 70.8 55 to 57 58.3 70.8 60 to 62 55.3 70.8 65 to 67 63.0 70.8 70 to 72 72.3 141.6 75 to 77 82.7 141.6 80 to 82 80.7 141.6 85 to 87 92.3 141.6 NUMBER OF PASSES 1 or 3 2 ASME stamping GAGE LOCATION (Cooler or Condenser) One gage in each waterbox Two gages in waterbox with nozzles HEAT EXCHANGER COOLER FIELD CONNECTION SIZE (FPT) 1′′ 1′′ 1′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 1′′ 1′′ 1′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ 11/4′′ PRESSURE GAGE LOCATION All 19XR heat exchangers are constructed in accordance with ASHRAE (American Society of Heating, Refrigera- tion, and Air Conditioning Engineers) 15 Safety Code for Mechanical Refrigeration (latest edition). This code, in turn, requires conformance with ASME (American Society of Mechanical Engineers) Code for Unfired Pressure Ves- sels wherever applicable. Each heat exchanger is ASME ‘U’ stamped on the refrig- erant side of each vessel. Relief valve discharge pipe sizing See pages 28 and 29 for number of relief valves. CONDENSER 30 Carrier further recommends that an oxygen sensor be installed to protect personnel. Sensor should be able to sense the depletion or displacement of oxygen in the ma- chine room below 19.5% volume oxygen per ASHRAE 15, latest edition.PDF Image | Carrier Product Data 19XR,XRV High-Efficiency Hermetic Centrifugal Liquid Chiller 50/60 Hz HFC-134a 19XR — 200 to 1500 Nominal Tons (703 to 5275 kW) 19XRV — 200 to 800 Nominal Tons (703 to 2813 kW)

PDF Search Title:

Carrier Product Data 19XR,XRV High-Efficiency Hermetic Centrifugal Liquid Chiller 50/60 Hz HFC-134a 19XR — 200 to 1500 Nominal Tons (703 to 5275 kW) 19XRV — 200 to 800 Nominal Tons (703 to 2813 kW)Original File Name Searched:

19XRdata.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |