PDF Publication Title:

Text from PDF Page: 003

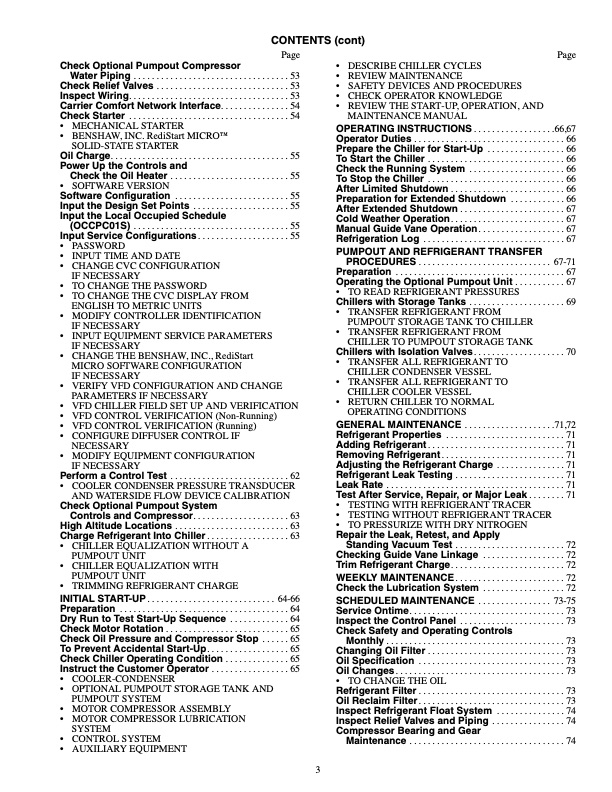

Page Check Optional Pumpout Compressor WaterPiping..................................53 CheckReliefValves.............................53 InspectWiring...................................53 CarrierComfortNetworkInterface...............54 CheckStarter ...................................54 • MECHANICAL STARTER • BENSHAW, INC. RediStart MICROTM SOLID-STATE STARTER Oil Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Power Up the Controls and Check the Oil Heater . . . . . . . . . . . . . . . . . . . . . . . . . . 55 • SOFTWARE VERSION SoftwareConfiguration .........................55 Input the Design Set Points . . . . . . . . . . . . . . . . . . . . . 55 Input the Local Occupied Schedule (OCCPC01S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Input Service Configurations. . . . . . . . . . . . . . . . . . . . 55 • PASSWORD • INPUT TIME AND DATE • CHANGE CVC CONFIGURATION IF NECESSARY • TO CHANGE THE PASSWORD • TO CHANGE THE CVC DISPLAY FROM ENGLISH TO METRIC UNITS • MODIFY CONTROLLER IDENTIFICATION IF NECESSARY • INPUT EQUIPMENT SERVICE PARAMETERS IF NECESSARY • CHANGE THE BENSHAW, INC., RediStart MICRO SOFTWARE CONFIGURATION IF NECESSARY • VERIFY VFD CONFIGURATION AND CHANGE PARAMETERS IF NECESSARY • VFD CHILLER FIELD SET UP AND VERIFICATION • VFD CONTROL VERIFICATION (Non-Running) • VFD CONTROL VERIFICATION (Running) • CONFIGURE DIFFUSER CONTROL IF NECESSARY • MODIFY EQUIPMENT CONFIGURATION IF NECESSARY PerformaControlTest..........................62 • COOLER CONDENSER PRESSURE TRANSDUCER AND WATERSIDE FLOW DEVICE CALIBRATION Check Optional Pumpout System ControlsandCompressor.....................63 HighAltitudeLocations.........................63 ChargeRefrigerantIntoChiller..................63 • CHILLER EQUALIZATION WITHOUT A PUMPOUT UNIT • CHILLER EQUALIZATION WITH PUMPOUT UNIT • TRIMMING REFRIGERANT CHARGE INITIALSTART-UP............................ 64-66 Preparation ..................................... 64 Page Dry Run to Test Start-Up Sequence . . . . . . . . . . Check Motor Rotation . . . . . . . . . . . . . . . . . . . . . . . . Check Oil Pressure and Compressor Stop . . . To Prevent Accidental Start-Up. . . . . . . . . . . . . . . Check Chiller Operating Condition . . . . . . . . . . . Instruct the Customer Operator . . . . . . . . . . . . . . • COOLER-CONDENSER • OPTIONAL PUMPOUT STORAGE TANK AND PUMPOUT SYSTEM • MOTOR COMPRESSOR ASSEMBLY • MOTOR COMPRESSOR LUBRICATION SYSTEM • CONTROL SYSTEM • AUXILIARY EQUIPMENT . . . 64 . . . 65 . . . 65 . . . 65 . . . 65 . . . 65 • DESCRIBE CHILLER CYCLES • REVIEW MAINTENANCE • SAFETY DEVICES AND PROCEDURES • CHECK OPERATOR KNOWLEDGE • REVIEW THE START-UP, OPERATION, AND MAINTENANCE MANUAL OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . .66,67 Operator Duties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 PreparetheChillerforStart-Up .................66 To Start the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 ChecktheRunningSystem ..................... 66 ToStoptheChiller .............................. 66 AfterLimitedShutdown......................... 66 PreparationforExtendedShutdown ............66 AfterExtendedShutdown....................... 67 Cold Weather Operation. . . . . . . . . . . . . . . . . . . . . . . . . 67 Manual Guide Vane Operation. . . . . . . . . . . . . . . . . . . 67 RefrigerationLog ...............................67 PUMPOUT AND REFRIGERANT TRANSFER PROCEDURES............................. 67-71 Preparation ..................................... 67 OperatingtheOptionalPumpoutUnit........... 67 • TO READ REFRIGERANT PRESSURES Chillers with Storage Tanks . . . . . . . . . . . . . . . . . . . . . 69 • TRANSFER REFRIGERANT FROM PUMPOUT STORAGE TANK TO CHILLER • TRANSFER REFRIGERANT FROM CHILLER TO PUMPOUT STORAGE TANK Chillers with Isolation Valves. . . . . . . . . . . . . . . . . . . . 70 • TRANSFER ALL REFRIGERANT TO CHILLER CONDENSER VESSEL • TRANSFER ALL REFRIGERANT TO CHILLER COOLER VESSEL • RETURN CHILLER TO NORMAL OPERATING CONDITIONS GENERALMAINTENANCE....................71,72 RefrigerantProperties .......................... 71 AddingRefrigerant.............................. 71 RemovingRefrigerant........................... 71 AdjustingtheRefrigerantCharge...............71 RefrigerantLeakTesting........................ 71 LeakRate.......................................71 Test After Service, Repair, or Major Leak. . . . . . . . 71 • TESTING WITH REFRIGERANT TRACER • TESTING WITHOUT REFRIGERANT TRACER • TO PRESSURIZE WITH DRY NITROGEN Repair the Leak, Retest, and Apply Standing Vacuum Test . . . . . . . . . . . . . . . . . . . . . . . . 72 CheckingGuideVaneLinkage ..................72 TrimRefrigerantCharge......................... 72 WEEKLYMAINTENANCE........................ 72 ChecktheLubricationSystem .................. 72 SCHEDULEDMAINTENANCE ................ 73-75 ServiceOntime.................................. 73 Inspect the Control Panel . . . . . . . . . . . . . . . . . . . . . . . 73 Check Safety and Operating Controls Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 ChangingOilFilter.............................. 73 OilSpecification ................................ 73 Oil Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 • TO CHANGE THE OIL RefrigerantFilter................................ 73 OilReclaimFilter................................ 73 InspectRefrigerantFloatSystem ...............74 Inspect Relief Valves and Piping . . . . . . . . . . . . . . . . 74 Compressor Bearing and Gear Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 CONTENTS (cont) 3PDF Image | Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a Start-Up, Operation, and Maintenance Instructions Safety Considerations

PDF Search Title:

Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a Start-Up, Operation, and Maintenance Instructions Safety ConsiderationsOriginal File Name Searched:

19xr-4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |