PDF Publication Title:

Text from PDF Page: 002

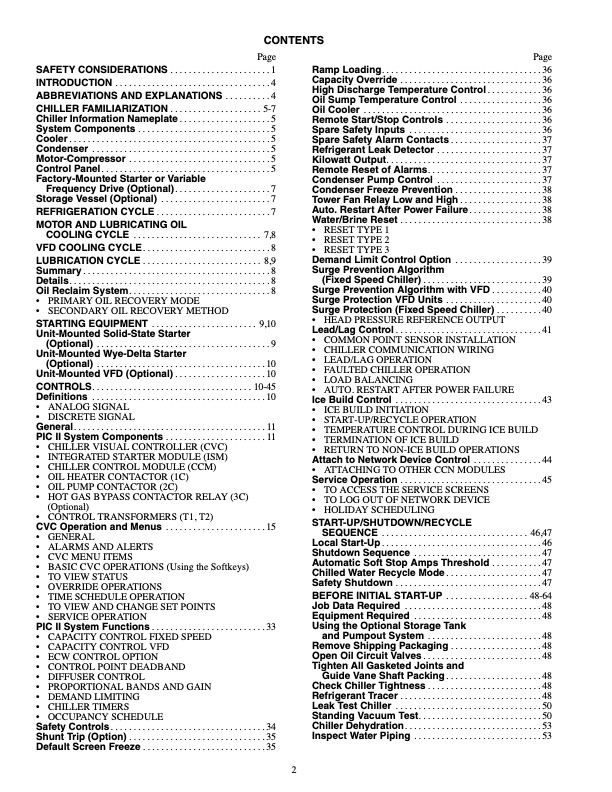

Page SAFETYCONSIDERATIONS......................1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 ABBREVIATIONS AND EXPLANATIONS . . . . . . . . . . 4 CHILLERFAMILIARIZATION.................... 5-7 ChillerInformationNameplate....................5 SystemComponents.............................5 Cooler............................................5 Condenser .......................................5 Motor-Compressor ...............................5 ControlPanel.....................................5 Factory-Mounted Starter or Variable FrequencyDrive(Optional).....................7 StorageVessel(Optional) ........................7 REFRIGERATION CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . 7 MOTOR AND LUBRICATING OIL COOLINGCYCLE ............................ 7,8 VFD COOLING CYCLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 LUBRICATIONCYCLE.......................... 8,9 Summary.........................................8 Details............................................8 OilReclaimSystem...............................8 • PRIMARY OIL RECOVERY MODE • SECONDARY OIL RECOVERY METHOD STARTINGEQUIPMENT ....................... 9,10 Unit-Mounted Solid-State Starter (Optional) ......................................9 Unit-Mounted Wye-Delta Starter (Optional) .....................................10 Unit-Mounted VFD (Optional) . . . . . . . . . . . . . . . . . . . . 10 CONTROLS................................... 10-45 Definitions ......................................10 • ANALOG SIGNAL • DISCRETE SIGNAL General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 PIC II System Components . . . . . . . . . . . . . . . . . . . . . . 11 • CHILLER VISUAL CONTROLLER (CVC) • INTEGRATED STARTER MODULE (ISM) • CHILLER CONTROL MODULE (CCM) • OIL HEATER CONTACTOR (1C) • OIL PUMP CONTACTOR (2C) • HOT GAS BYPASS CONTACTOR RELAY (3C) (Optional) • CONTROL TRANSFORMERS (T1, T2) CVCOperationandMenus ......................15 • GENERAL • ALARMS AND ALERTS • CVC MENU ITEMS • BASIC CVC OPERATIONS (Using the Softkeys) • TO VIEW STATUS • OVERRIDE OPERATIONS • TIME SCHEDULE OPERATION • TO VIEW AND CHANGE SET POINTS • SERVICE OPERATION PICIISystemFunctions.........................33 • CAPACITY CONTROL FIXED SPEED • CAPACITY CONTROL VFD • ECW CONTROL OPTION • CONTROL POINT DEADBAND • DIFFUSER CONTROL • PROPORTIONAL BANDS AND GAIN • DEMAND LIMITING • CHILLER TIMERS • OCCUPANCY SCHEDULE SafetyControls..................................34 ShuntTrip(Option)..............................35 Default Screen Freeze . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Page RampLoading................................. ..36 Capacity Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 High Discharge Temperature Control . . . . . . . . . . . . 36 Oil Sump Temperature Control . . . . . . . . . . . . . . . . . . 36 OilCooler .......................................36 RemoteStart/StopControls.....................36 SpareSafetyInputs .............................36 SpareSafetyAlarmContacts....................37 RefrigerantLeakDetector.......................37 KilowattOutput..................................37 RemoteResetofAlarms.........................37 CondenserPumpControl .......................37 CondenserFreezePrevention...................38 TowerFanRelayLowandHigh..................38 Auto. Restart After Power Failure. . . . . . . . . . . . . . . . 38 Water/Brine Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 • RESET TYPE 1 • RESET TYPE 2 • RESET TYPE 3 DemandLimitControlOption ...................39 Surge Prevention Algorithm (Fixed Speed Chiller) . . . . . . . . . . . . . . . . . . . . . . . . . . 39 SurgePreventionAlgorithmwithVFD...........40 SurgeProtectionVFDUnits.....................40 Surge Protection (Fixed Speed Chiller) . . . . . . . . . . 40 • HEAD PRESSURE REFERENCE OUTPUT Lead/Lag Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 • COMMON POINT SENSOR INSTALLATION • CHILLER COMMUNICATION WIRING • LEAD/LAG OPERATION • FAULTED CHILLER OPERATION • LOAD BALANCING • AUTO. RESTART AFTER POWER FAILURE IceBuildControl ................................43 • ICE BUILD INITIATION • START-UP/RECYCLE OPERATION • TEMPERATURE CONTROL DURING ICE BUILD • TERMINATION OF ICE BUILD • RETURN TO NON-ICE BUILD OPERATIONS AttachtoNetworkDeviceControl ...............44 • ATTACHING TO OTHER CCN MODULES Service Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 • TO ACCESS THE SERVICE SCREENS • TO LOG OUT OF NETWORK DEVICE • HOLIDAY SCHEDULING START-UP/SHUTDOWN/RECYCLE SEQUENCE ................................ 46,47 Local Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 ShutdownSequence ............................47 Automatic Soft Stop Amps Threshold . . . . . . . . . . . 47 Chilled Water Recycle Mode . . . . . . . . . . . . . . . . . . . . . 47 Safety Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47 BEFOREINITIALSTART-UP..................48-64 JobDataRequired ..............................48 EquipmentRequired ............................48 Using the Optional Storage Tank andPumpoutSystem .........................48 RemoveShippingPackaging....................48 OpenOilCircuitValves..........................48 Tighten All Gasketed Joints and Guide Vane Shaft Packing . . . . . . . . . . . . . . . . . . . . . 48 CheckChillerTightness.........................48 RefrigerantTracer...............................48 LeakTestChiller ................................50 StandingVacuumTest...........................50 ChillerDehydration..............................53 InspectWaterPiping ............................53 CONTENTS 2PDF Image | Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a Start-Up, Operation, and Maintenance Instructions Safety Considerations

PDF Search Title:

Carrier 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a Start-Up, Operation, and Maintenance Instructions Safety ConsiderationsOriginal File Name Searched:

19xr-4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |