PDF Publication Title:

Text from PDF Page: 029

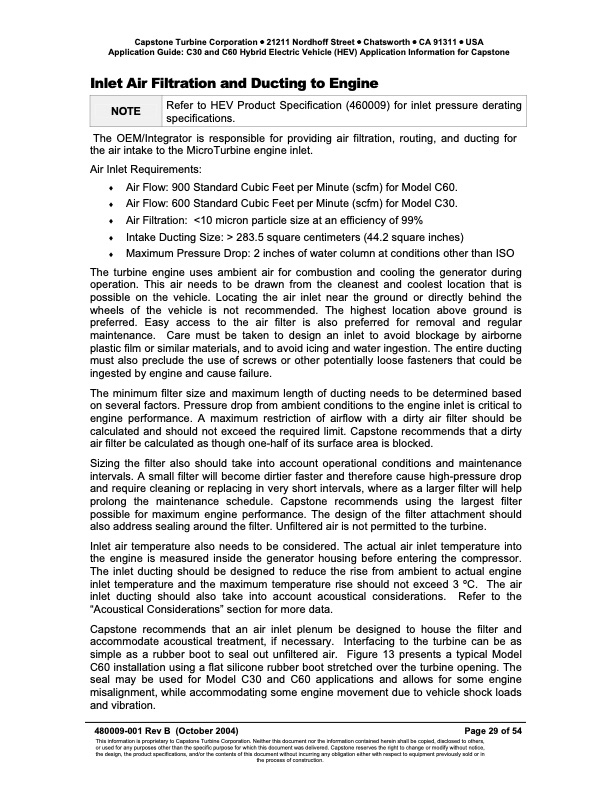

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: C30 and C60 Hybrid Electric Vehicle (HEV) Application Information for Capstone Inlet Air Filtration and Ducting to Engine NOTE Refer to HEV Product Specification (460009) for inlet pressure derating specifications. The OEM/Integrator is responsible for providing air filtration, routing, and ducting for the air intake to the MicroTurbine engine inlet. Air Inlet Requirements: ♦ Air Flow: 900 Standard Cubic Feet per Minute (scfm) for Model C60. ♦ Air Flow: 600 Standard Cubic Feet per Minute (scfm) for Model C30. ♦ Air Filtration: <10 micron particle size at an efficiency of 99% ♦ Intake Ducting Size: > 283.5 square centimeters (44.2 square inches) ♦ Maximum Pressure Drop: 2 inches of water column at conditions other than ISO The turbine engine uses ambient air for combustion and cooling the generator during operation. This air needs to be drawn from the cleanest and coolest location that is possible on the vehicle. Locating the air inlet near the ground or directly behind the wheels of the vehicle is not recommended. The highest location above ground is preferred. Easy access to the air filter is also preferred for removal and regular maintenance. Care must be taken to design an inlet to avoid blockage by airborne plastic film or similar materials, and to avoid icing and water ingestion. The entire ducting must also preclude the use of screws or other potentially loose fasteners that could be ingested by engine and cause failure. The minimum filter size and maximum length of ducting needs to be determined based on several factors. Pressure drop from ambient conditions to the engine inlet is critical to engine performance. A maximum restriction of airflow with a dirty air filter should be calculated and should not exceed the required limit. Capstone recommends that a dirty air filter be calculated as though one-half of its surface area is blocked. Sizing the filter also should take into account operational conditions and maintenance intervals. A small filter will become dirtier faster and therefore cause high-pressure drop and require cleaning or replacing in very short intervals, where as a larger filter will help prolong the maintenance schedule. Capstone recommends using the largest filter possible for maximum engine performance. The design of the filter attachment should also address sealing around the filter. Unfiltered air is not permitted to the turbine. Inlet air temperature also needs to be considered. The actual air inlet temperature into the engine is measured inside the generator housing before entering the compressor. The inlet ducting should be designed to reduce the rise from ambient to actual engine inlet temperature and the maximum temperature rise should not exceed 3 oC. The air inlet ducting should also take into account acoustical considerations. Refer to the ìAcoustical Considerationsî section for more data. Capstone recommends that an air inlet plenum be designed to house the filter and accommodate acoustical treatment, if necessary. Interfacing to the turbine can be as simple as a rubber boot to seal out unfiltered air. Figure 13 presents a typical Model C60 installation using a flat silicone rubber boot stretched over the turbine opening. The seal may be used for Model C30 and C60 applications and allows for some engine misalignment, while accommodating some engine movement due to vehicle shock loads and vibration. 480009-001 Rev B (October 2004) Page 29 of 54 This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Application Guide Model C30 and C60 HEV Application Information

PDF Search Title:

Application Guide Model C30 and C60 HEV Application InformationOriginal File Name Searched:

480009_HEV_Application_Guide.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |