PDF Publication Title:

Text from PDF Page: 003

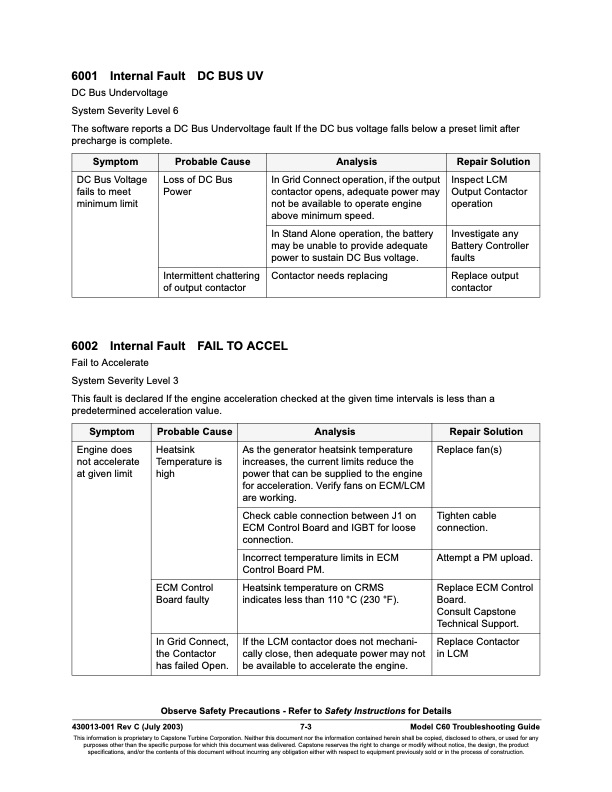

6001 Internal Fault DC BUS UV DC Bus Undervoltage System Severity Level 6 The software reports a DC Bus Undervoltage fault If the DC bus voltage falls below a preset limit after precharge is complete. Symptom Probable Cause Analysis Repair Solution DC Bus Voltage fails to meet minimum limit Loss of DC Bus Power In Grid Connect operation, if the output contactor opens, adequate power may not be available to operate engine above minimum speed. Inspect LCM Output Contactor operation In Stand Alone operation, the battery may be unable to provide adequate power to sustain DC Bus voltage. Investigate any Battery Controller faults Intermittent chattering of output contactor Contactor needs replacing Replace output contactor 6002 Internal Fault FAIL TO ACCEL Fail to Accelerate System Severity Level 3 This fault is declared If the engine acceleration checked at the given time intervals is less than a predetermined acceleration value. Symptom Probable Cause Analysis Repair Solution Engine does not accelerate at given limit Heatsink Temperature is high As the generator heatsink temperature increases, the current limits reduce the power that can be supplied to the engine for acceleration. Verify fans on ECM/LCM are working. Replace fan(s) Check cable connection between J1 on ECM Control Board and IGBT for loose connection. Tighten cable connection. Incorrect temperature limits in ECM Control Board PM. Attempt a PM upload. ECM Control Board faulty Heatsink temperature on CRMS indicates less than 110 °C (230 °F). Replace ECM Control Board. Consult Capstone Technical Support. In Grid Connect, the Contactor has failed Open. If the LCM contactor does not mechani- cally close, then adequate power may not be available to accelerate the engine. Replace Contactor in LCM Observe Safety Precautions - Refer to Safety Instructions for Details 430013-001 Rev C (July 2003) 7-3 Model C60 Troubleshooting Guide This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Overview SERIES 6000 FAULT CODES Operational Faults

PDF Search Title:

Overview SERIES 6000 FAULT CODES Operational FaultsOriginal File Name Searched:

C60_07_6000 Faults.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |