PDF Publication Title:

Text from PDF Page: 017

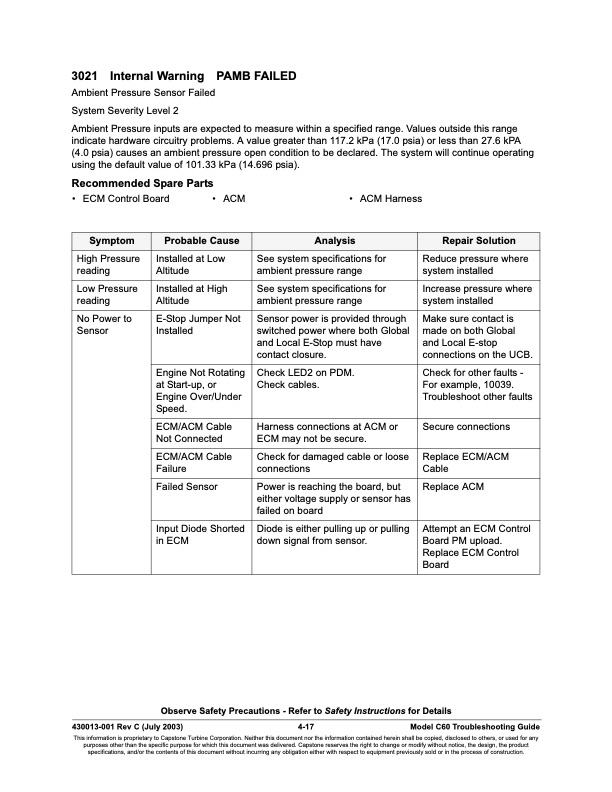

3021 Internal Warning PAMB FAILED Ambient Pressure Sensor Failed System Severity Level 2 Ambient Pressure inputs are expected to measure within a specified range. Values outside this range indicate hardware circuitry problems. A value greater than 117.2 kPa (17.0 psia) or less than 27.6 kPA (4.0 psia) causes an ambient pressure open condition to be declared. The system will continue operating using the default value of 101.33 kPa (14.696 psia). Recommended Spare Parts • ECM Control Board • ACM • ACM Harness Symptom Probable Cause Analysis Repair Solution High Pressure reading Installed at Low Altitude See system specifications for ambient pressure range Reduce pressure where system installed Low Pressure reading Installed at High Altitude See system specifications for ambient pressure range Increase pressure where system installed No Power to Sensor E-Stop Jumper Not Installed Sensor power is provided through switched power where both Global and Local E-Stop must have contact closure. Make sure contact is made on both Global and Local E-stop connections on the UCB. Engine Not Rotating at Start-up, or Engine Over/Under Speed. Check LED2 on PDM. Check cables. Check for other faults - For example, 10039. Troubleshoot other faults ECM/ACM Cable Not Connected Harness connections at ACM or ECM may not be secure. Secure connections ECM/ACM Cable Failure Check for damaged cable or loose connections Replace ECM/ACM Cable Failed Sensor Power is reaching the board, but either voltage supply or sensor has failed on board Replace ACM Input Diode Shorted in ECM Diode is either pulling up or pulling down signal from sensor. Attempt an ECM Control Board PM upload. Replace ECM Control Board Observe Safety Precautions - Refer to Safety Instructions for Details 430013-001 Rev C (July 2003) 4-17 Model C60 Troubleshooting Guide This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Overview SERIES 3000 FAULT CODES Sensor Faults

PDF Search Title:

Overview SERIES 3000 FAULT CODES Sensor FaultsOriginal File Name Searched:

C60_04_3000 Faults.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |