PDF Publication Title:

Text from PDF Page: 007

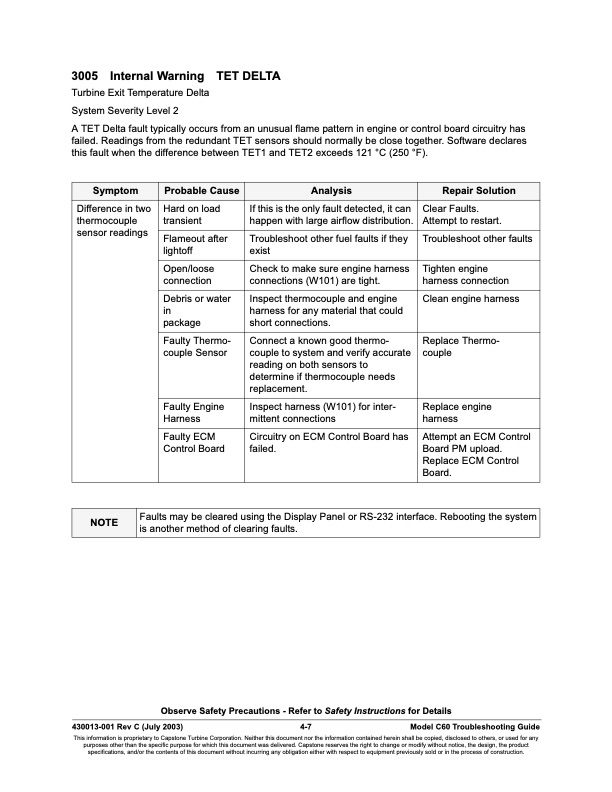

3005 Internal Warning TET DELTA Turbine Exit Temperature Delta System Severity Level 2 A TET Delta fault typically occurs from an unusual flame pattern in engine or control board circuitry has failed. Readings from the redundant TET sensors should normally be close together. Software declares this fault when the difference between TET1 and TET2 exceeds 121 °C (250 °F). Symptom Probable Cause Analysis Repair Solution Difference in two thermocouple sensor readings Hard on load transient If this is the only fault detected, it can happen with large airflow distribution. Clear Faults. Attempt to restart. Flameout after lightoff Troubleshoot other fuel faults if they exist Troubleshoot other faults Open/loose connection Check to make sure engine harness connections (W101) are tight. Tighten engine harness connection Debris or water in package Inspect thermocouple and engine harness for any material that could short connections. Clean engine harness Faulty Thermo- couple Sensor Connect a known good thermo- couple to system and verify accurate reading on both sensors to determine if thermocouple needs replacement. Replace Thermo- couple Faulty Engine Harness Inspect harness (W101) for inter- mittent connections Replace engine harness Faulty ECM Control Board Circuitry on ECM Control Board has failed. Attempt an ECM Control Board PM upload. Replace ECM Control Board. NOTE Faults may be cleared using the Display Panel or RS-232 interface. Rebooting the system is another method of clearing faults. Observe Safety Precautions - Refer to Safety Instructions for Details 430013-001 Rev C (July 2003) 4-7 Model C60 Troubleshooting Guide This information is proprietary to Capstone Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Overview SERIES 3000 FAULT CODES Sensor Faults

PDF Search Title:

Overview SERIES 3000 FAULT CODES Sensor FaultsOriginal File Name Searched:

C60_04_3000 Faults.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |