PDF Publication Title:

Text from PDF Page: 011

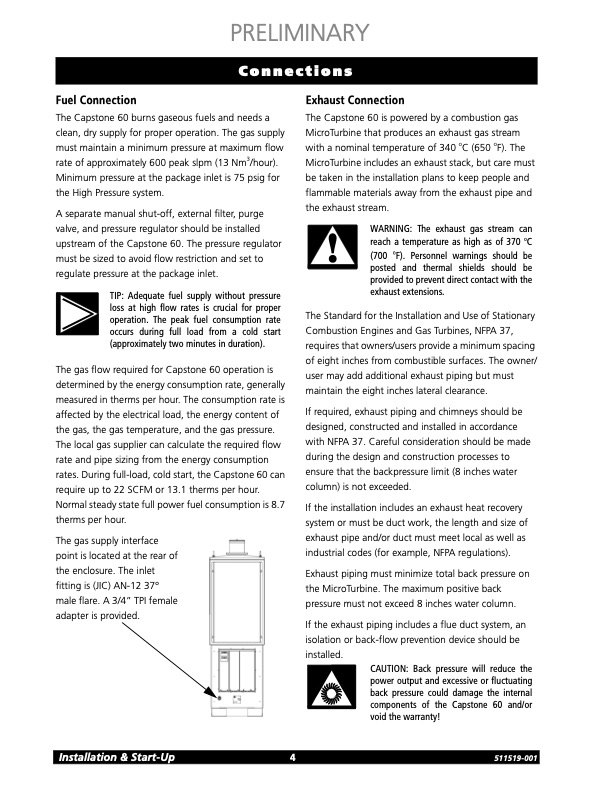

PRELIMINARY Connections Fuel Connection The Capstone 60 burns gaseous fuels and needs a clean, dry supply for proper operation. The gas supply must maintain a minimum pressure at maximum flow rate of approximately 600 peak slpm (13 Nm3/hour). Minimum pressure at the package inlet is 75 psig for the High Pressure system. A separate manual shut-off, external filter, purge valve, and pressure regulator should be installed upstream of the Capstone 60. The pressure regulator must be sized to avoid flow restriction and set to regulate pressure at the package inlet. TIP: Adequate fuel supply without pressure loss at high flow rates is crucial for proper operation. The peak fuel consumption rate occurs during full load from a cold start (approximately two minutes in duration). The gas flow required for Capstone 60 operation is determined by the energy consumption rate, generally measured in therms per hour. The consumption rate is affected by the electrical load, the energy content of the gas, the gas temperature, and the gas pressure. The local gas supplier can calculate the required flow rate and pipe sizing from the energy consumption rates. During full-load, cold start, the Capstone 60 can require up to 22 SCFM or 13.1 therms per hour. Normal steady state full power fuel consumption is 8.7 therms per hour. The gas supply interface point is located at the rear of the enclosure. The inlet fitting is (JIC) AN-12 37o male flare. A 3/4” TPI female adapter is provided. Exhaust Connection The Capstone 60 is powered by a combustion gas MicroTurbine that produces an exhaust gas stream with a nominal temperature of 340 oC (650 oF). The MicroTurbine includes an exhaust stack, but care must be taken in the installation plans to keep people and flammable materials away from the exhaust pipe and the exhaust stream. WARNING: The exhaust gas stream can reach a temperature as high as of 370 oC (700 oF). Personnel warnings should be posted and thermal shields should be provided to prevent direct contact with the exhaust extensions. The Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines, NFPA 37, requires that owners/users provide a minimum spacing of eight inches from combustible surfaces. The owner/ user may add additional exhaust piping but must maintain the eight inches lateral clearance. If required, exhaust piping and chimneys should be designed, constructed and installed in accordance with NFPA 37. Careful consideration should be made during the design and construction processes to ensure that the backpressure limit (8 inches water column) is not exceeded. If the installation includes an exhaust heat recovery system or must be duct work, the length and size of exhaust pipe and/or duct must meet local as well as industrial codes (for example, NFPA regulations). Exhaust piping must minimize total back pressure on the MicroTurbine. The maximum positive back pressure must not exceed 8 inches water column. If the exhaust piping includes a flue duct system, an isolation or back-flow prevention device should be installed. CAUTION: Back pressure will reduce the power output and excessive or fluctuating back pressure could damage the internal components of the Capstone 60 and/or void the warranty! Installation & Start-Up 4 511519-001PDF Image | C60 Mech

PDF Search Title:

C60 MechOriginal File Name Searched:

c60installation.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |