PDF Publication Title:

Text from PDF Page: 006

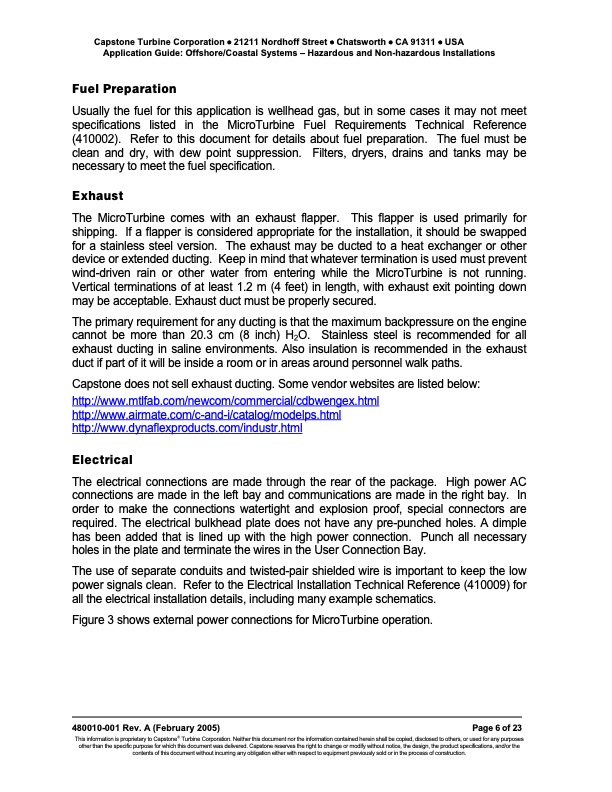

Capstone Turbine Corporation • 21211 Nordhoff Street • Chatsworth • CA 91311 • USA Application Guide: Offshore/Coastal Systems – Hazardous and Non-hazardous Installations Fuel Preparation Usually the fuel for this application is wellhead gas, but in some cases it may not meet specifications listed in the MicroTurbine Fuel Requirements Technical Reference (410002). Refer to this document for details about fuel preparation. The fuel must be clean and dry, with dew point suppression. Filters, dryers, drains and tanks may be necessary to meet the fuel specification. Exhaust The MicroTurbine comes with an exhaust flapper. This flapper is used primarily for shipping. If a flapper is considered appropriate for the installation, it should be swapped for a stainless steel version. The exhaust may be ducted to a heat exchanger or other device or extended ducting. Keep in mind that whatever termination is used must prevent wind-driven rain or other water from entering while the MicroTurbine is not running. Vertical terminations of at least 1.2 m (4 feet) in length, with exhaust exit pointing down may be acceptable. Exhaust duct must be properly secured. The primary requirement for any ducting is that the maximum backpressure on the engine cannot be more than 20.3 cm (8 inch) H2O. Stainless steel is recommended for all exhaust ducting in saline environments. Also insulation is recommended in the exhaust duct if part of it will be inside a room or in areas around personnel walk paths. Capstone does not sell exhaust ducting. Some vendor websites are listed below: http://www.mtlfab.com/newcom/commercial/cdbwengex.html http://www.airmate.com/c-and-i/catalog/modelps.html http://www.dynaflexproducts.com/industr.html Electrical The electrical connections are made through the rear of the package. High power AC connections are made in the left bay and communications are made in the right bay. In order to make the connections watertight and explosion proof, special connectors are required. The electrical bulkhead plate does not have any pre-punched holes. A dimple has been added that is lined up with the high power connection. Punch all necessary holes in the plate and terminate the wires in the User Connection Bay. The use of separate conduits and twisted-pair shielded wire is important to keep the low power signals clean. Refer to the Electrical Installation Technical Reference (410009) for all the electrical installation details, including many example schematics. Figure 3 shows external power connections for MicroTurbine operation. 480010-001 Rev. A (February 2005) Page 6 of 23 This information is proprietary to Capstone® Turbine Corporation. Neither this document nor the information contained herein shall be copied, disclosed to others, or used for any purposes other than the specific purpose for which this document was delivered. Capstone reserves the right to change or modify without notice, the design, the product specifications, and/or the contents of this document without incurring any obligation either with respect to equipment previously sold or in the process of construction.PDF Image | Application Guide Offshore/Coastal Systems - Hazardous and Non-Hazardous Installation Options for the Capstone MicroTurbine

PDF Search Title:

Application Guide Offshore/Coastal Systems - Hazardous and Non-Hazardous Installation Options for the Capstone MicroTurbineOriginal File Name Searched:

appguide_480010-001.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |