PDF Publication Title:

Text from PDF Page: 006

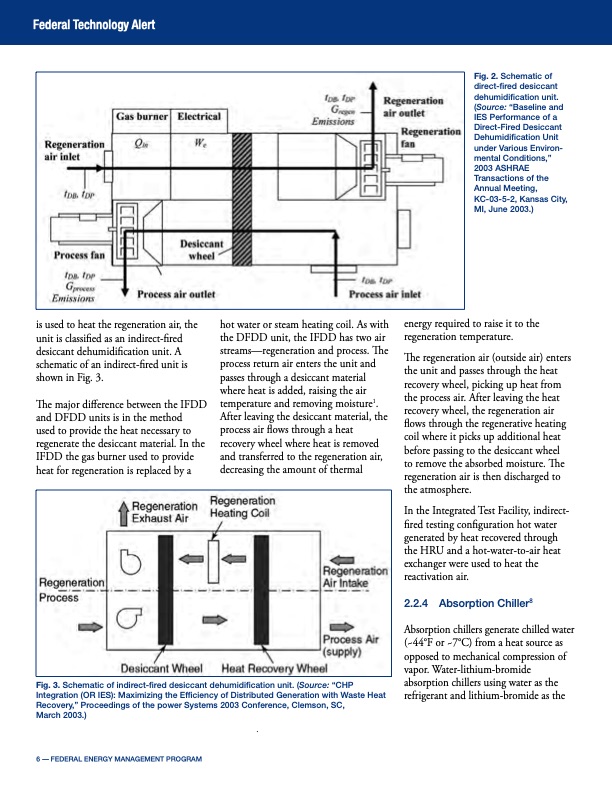

Federal Technology Alert is used to heat the regeneration air, the unit is classified as an indirect-fired desiccant dehumidification unit. A schematic of an indirect-fired unit is shown in Fig. 3. The major difference between the IFDD and DFDD units is in the method used to provide the heat necessary to regenerate the desiccant material. In the IFDD the gas burner used to provide heat for regeneration is replaced by a hot water or steam heating coil. As with the DFDD unit, the IFDD has two air streams—regeneration and process. The process return air enters the unit and passes through a desiccant material where heat is added, raising the air temperature and removing moisture1. After leaving the desiccant material, the process air flows through a heat recovery wheel where heat is removed and transferred to the regeneration air, decreasing the amount of thermal Fig. 2. Schematic of direct-fired desiccant dehumidification unit. (Source: “Baseline and IES Performance of a Direct-Fired Desiccant Dehumidification Unit under Various Environ mental Conditions,” 2003 ASHRAE Transactions of the Annual Meeting, KC-03-5-2, Kansas City, MI, June 2003.) energy required to raise it to the regeneration temperature. The regeneration air (outside air) enters the unit and passes through the heat recovery wheel, picking up heat from the process air. After leaving the heat recovery wheel, the regeneration air flows through the regenerative heating coil where it picks up additional heat before passing to the desiccant wheel to remove the absorbed moisture. The regeneration air is then discharged to the atmosphere. In the Integrated Test Facility, indirect- fired testing configuration hot water generated by heat recovered through the HRU and a hot-water-to-air heat exchanger were used to heat the reactivation air. 2.2.4 Absorption Chiller8 Absorption chillers generate chilled water (~44°F or ~7°C) from a heat source as opposed to mechanical compression of vapor. Water-lithium-bromide absorption chillers using water as the refrigerant and lithium-bromide as the Fig. 3. Schematic of indirect-fired desiccant dehumidification unit. (Source: “CHP Integration (OR IES): Maximizing the Efficiency of Distributed Generation with Waste Heat Recovery,” Proceedings of the power Systems 2003 Conference, Clemson, SC, March 2003.) 6 –– FEDERAL ENERGY MANAGEMENT PROGRAM .PDF Image | Summary of Results from Testing a 30-kW-Microturbine and Combined Heat and Power (CHP) System

PDF Search Title:

Summary of Results from Testing a 30-kW-Microturbine and Combined Heat and Power (CHP) SystemOriginal File Name Searched:

fta_microturbinechp.pdfDIY PDF Search: Google It | Yahoo | Bing

Capstone Turbine and Microturbine: Capstone microturbines used and new surplus for sale listing More Info

Consulting and Strategy Services: Need help with Capstone Turbine, sizing systems, applications, or renewable energy strategy, we are here to assist More Info

Container Lumber Dry Kiln: Since 1991 developing and innovating dry kilns using standard shipping containers More Info

Supercritical CO2 Lumber Dry Kiln: Compact fast drying in 3 days or less for small amounts of wood and lumber drying More Info

BitCoin Mining: Bitcoin Mining and Cryptocurrency... More Info

Publications: Capstone Turbine publications for microturbine and distributed energy More Info

FileMaker Software for Renewable Energy Developing database software for the renewable energy industry More Info

CO2 Gas to Liquids On-Demand Production Cart Developing a supercritical CO2 to alcohol on-demand production system (via Nafion reverse fuel cell) More Info

Stranded Gas for low cost power Bitcoin Mining Using stranded gas for generators may provide breakthrough low power costs for cryptocurrency miners. More Info

| CONTACT TEL: 608-238-6001 Email: greg@globalmicroturbine.com | RSS | AMP |